Following on from many questions we receive about testing for “rapidly matured” spirits, and from a visit, in June, to the Worldwide Distilled Spirits Conference held in Glasgow, Scotland, a short review of some factors and variables that play a role in the maturation of distilled spirits seemed to be of potential use for the modern-day distiller.

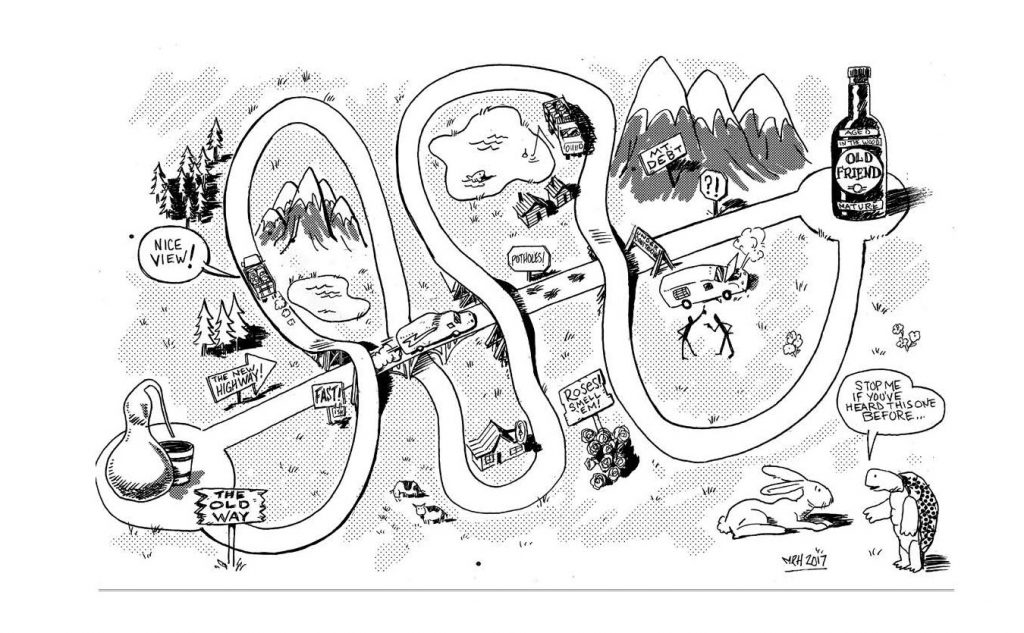

Overview: This paper (in three parts) has been prepared for today’s distiller to better understand the complexity of distilled-spirits maturation. Recently, many attempts have been made by craft distillers to design process systems to bypass the traditional multi-years-long maturation stage (McLafferty, 2016). And many requests are asked of laboratories to test these products in hopes of being able to lay stake to a claim that they have been successful in this regard. Yet, without a fuller understanding of the physics and chemistry involved, the advocates of rapid-maturation might be onto a futile exercise, despite some successes in the arena as judged by various and perhaps less-than-expert-level competition results; the wine industry has seen a similar fiasco with respect to so-called expert judging (Hodgson, 2009). Sensory evaluation is as complex a topic as understanding the chemistry behind spirits production and maturation! That said: “The quality of a beverage such as whiskey is judged by the consumer on its properties affecting taste and odor” (Liebmann and Rosenblatt, 1943). How the taste, aroma and other sensory qualities arise forms the focus of this article. And it may be slow in coming — hence the need for years of dark, silent chemistry.

Part 1 of this article covers 11 key analytics for judging the maturation of distilled whiskeys, based on research started over 80 years ago. The discussion will evaluate some of the possible secrets uncovered on the potential for rapid maturation and provide hints as to why the issue has not been resolved. Even 80 years on, with a wealth of detailed research and new technologies, there is no degree of certainty, at least in the public domain, that we are anywhere close today.

As ethanol and water are the key solvent ingredients in the process of spirits production and maturation, their properties will also be covered here in part 1. This will touch upon characteristics of unaged spirits before leading into aging of spirits in the wood. A brief introduction then deals with the impact of the many congeners, both volatile and nonvolatile in nature, a minor fraction of components, though vast in number. This will provide the lead into part 2, which will cover the actual maturation process in some detail. The complexity of maturation cannot be overstated and, while the major distillers and the distillers’ member-based scientific groups likely have uncovered most of the necessary details, the question still must be asked as to why, after 80 years, do we not see the major players rapidly maturing their distilled spirits? Any successful attempts at bypassing the long, quiet aging process will most likely come about once the vast physicochemical “spirit and barrel” engine or machine is more completely understood. The two parts of this article will provide a brief glimpse of the author’s perspective as to how that future might look.

Introduction

It begins with a former distilling company giant called Schenley and a researcher named Liebmann.

In 1937, the Schenley Research Institute initiated an extensive set of experiments, which were designed to look at maturation events and the timing involved with respect to bourbon and rye whiskeys. (Results of the initial four-year study and subsequent work can be found here: Liebmann and Rosenblatt, 1943; Liebmann and Scherl, 1949). The study was an important one and has largely been forgotten by modern-day distillers. Today, craft distillers are trying to reinvent the wheel with rapid-maturation methods, but the major early players in spirits production went through the same process of trying to get product to market quickly and bypassing the traditional aging process. A brief review of the results from the 1937 grand experiment reveals several key analytical tests to be performed for judging the maturation and time for release of spirits (some were deemed to be not of further importance; see below). Interestingly, many of the items in the list are required tests for the U.S. Tax and Trade Bureau (TTB) export certification program, so distillers should at least familiarize themselves with this section of the paper. Other secrets to maturation are also embedded in these works (Liebmann and Rosenblatt, 1943; Liebmann and Scherl, 1949) and some will be revealed in this discussion and in the second part of this article.

The overall quality of a distilled spirit depends on the raw materials (and their preparation and processing — milling and mashing) including process and dilution water, and upon fermentation, distillation and maturation. With the modern focus on completing maturation in rapid time, the desire to design an efficient, rapid time machine seems to have become more important to many distillers than understanding the chemistry that leads to the creation of a consumer-acceptable, and appropriately “matured” full-flavored product of distinct character. Many of the products of accelerated aging techniques mimic characteristics that are found in fully-matured spirits but are lacking in balance, subtlety and nuance. They are missing some of the long-chain compounds, esters and many other constituents that we have only recently learned are produced with years of quiet, slow reactions taking place inside slumbering dark barrels.

1937 and all that!

A full statistical analysis was undertaken, by the Schenley research team, of 11 characteristics used as the basis for the maturation status of bourbon and rye whiskeys (Liebmann and Rosenblatt, 1943; Liebmann and Scherl, 1949). The list, with some notes, is provided below. A main point here is that a few simple tests, such as alcohol content and color, along with some basic tastings, simply will not suffice to judge the overall quality and readiness for bottling of an aged spirit. Also, an understanding of the significance of the results is important (and not solely because they appear, for example, on the required test list for the TTB or other regulatory compliance agencies). Noting again that the tests were run on bourbon and rye whiskeys, the quality parameters will apply equally well to other aged spirits and in some cases to unaged or white spirits.

“The development of quality therefore, involves specific chemical and physical changes in the properties of the liquid, some of which are relatively simple to determine. These properties, or characteristics, are commonly used as a guide to and measure of quality — leading indicators! Experience and observation have shown that abnormalities arising in one or several of the physico-chemical characteristics will generally result in abnormalities of the taste characteristics of the liquid.” (Liebmann and Rosenblatt, 1943). Some of the distillers who have tried to accelerate aging, while not yet producing examples that hold the nuance of fully matured spirits, have also pushed the need to understand what goes on inside the barrel, therefore increasing our scientific understanding as to what tradition has taught us over centuries; in slow stages they are leading us to better things than they were able to in the past and may lead us to new attainable and desirable methods of flavor creation.

Constituent factors — the analysis of matured spirit components

The 11 major constituent factors, as determined over at least a four-year period from an extensive number of aging bourbon and rye whiskey samples by the Schenley researchers, are as follows.

- Proof (Temperature corrected, presumably at 60°F. Of course, the alcohol content must be determined as accurately as possible at many process points and in the finished product. The early tests of proof were done in part to relate to the other parameters, to learn if differences in alcohol proof had positive or negative effects upon maturation and to determine the state of the maturation process. Alcohol by volume (v/v) is expressed in this paper as % ABV unless quoted from other works.)

- Total acidity (Representing all the acids present in the spirit, though expressed as if all exist as the more volatile acid — acetic acid. Expressed as grams of acetic acid per 100 liters at 100 degrees proof. Acids may exist as free acids in solution or bound as complexes, hence fixed acidity. Interactions between the acids and the other chemical components are extremely complicated, yet each of these plays a role in the measurement of total acidity and in maturation reactions!)

- Fixed acidity (Measured as total acidity minus volatile acidity – the latter term not further discussed here. Very generally, pH is a quantitative assessment of fixed acidity. The concept of pH, though, is abstract and as such is not as important a parameter as understanding the relationship between acidity and balance in the spirit. Moreover, as will be seen in part 2, acidity levels bear upon the correct maturation of the spirit in the wood. Expressed as grams of acetic acid per 100 liters at 100 proof.)

- Esters (Measured by chemical means in the 1930s but today via gas chromatography. Ethyl acetate is the most common ester arising from fermentation and at later stages of distilled spirits production and appears in the heads portion of the distillate. It will be seen to be a major chemical player again in spirit maturation in part 2. As for the acids, many esters may be present in a spirit (each usually in relatively very small amounts), but as the most important ester-fraction component the expression of total esters is reported as for ethyl acetate only. Expressed as grams of ethyl acetate per 100 liters at 100 proof.)

- Aldehydes (A major chemical class involved in spirits flavor and off-flavor — discussed further in part 2. Measured by chemical means in the 1930s but today via gas chromatography. Expressed as grams of acetaldehyde per 100 liters at 100 proof.)

- Furfural (Another aldehyde, and related compounds are generated from sugars during heating — caramelization and Maillard reactions — and, from several viewpoints, are chemically important in alcohol beverage production. The results are expressed as grams of furfural per 100 liters at 100 proof. The report from 1943 suggested this was not an important parameter to judge aging quality by and might be dropped from standard test regimes going forward, although it is still included in the TTB export certification program. There will be much more on this in part 2!)

- Fusel oil (Collectively the higher alcohols are covered here but mainly isoamyl {3-methyl-1-butanol} and active amyl alcohol {2-methyl-1-butanol}. The group here, with higher boiling points than ethanol, appear in the tails fraction and are indicative, if in high-amounts, of poorly rectified spirit. While complex reactions take place in the wood involving fusel alcohols, discussed in part 2, the general levels delivered at barrel filling do not change with aging, giving the rubbing alcohol and pungent/solventy notes which are not desirable in a top-notch, carefully distilled spirit. Originally measured by cruder chemical tests, they are now determined as individual components via gas chromatography and collectively expressed typically as grams of amyl alcohol {fusel oils} per 100 liters at 100 proof.)

- Solids (Extracts and insoluble matter from wood maturation, determined via evaporation and weighing of the residue. Results expressed as grams per 100 liters at 100 proof. The 1943 paper indicated that this, like furfural, cannot be used as a reliable indicator of the age of whiskey; this will be argued in-depth in part 2. Of note here, though, before moving on to covering the solvent properties of spirits, is the fact that there are water-soluble barrel components and alcohol-soluble constituents of the wood. The difference in solubility relates to the fact that some substances are hydrophilic (water-loving) and some are hydrophobic (water-hating – meaning they prefer an organic solvent). Water is described as an aqueous solvent, while organic liquids are of course non-aqueous or simply organic solvents. Mixtures of both provide for unique solvent properties as discussed below.)

- Color (Measured in the 1930s with colorimeters and today by spectrophotometric means, usually on spirit at 100 proof or, as today, on finished spirit and reported as a value at a specified wavelength of visible light. Craft distillers often think this a good enough measure of the age of the spirit, although it is not a true indicator of taste information. Color is created in a myriad of ways, from charring and toasting of barrels, and from caramelization and Maillard reactions.)

- Tannins (An older method is still used today to measure the tannin materials in the aged spirit, tannins being a major wood component. This is a measure of the solvent extraction of the different fractions of tannins. Expressed as grams of tannic acid per 100 liters at 100 proof as determined by reference to standard curves. This may still be an important quality parameter for Scotch producers but, according to personal communications with bourbon distillers, surprisingly to this author, not as important for them today — so I suggest this also be questioned! From a taster’s standpoint, tannins seem a very important flavor component in whiskeys and in brandies. More on this in part 2.)

- pH (See note above under Fixed acidity. This was measured at 100 proof at 25°C, via use of a pH meter. Application and limitations of pH measurements were cited in Liebmann and Rosenblatt in 1943, but we can state again that pH is, very generally, a quantitative assessment of fixed acidity. The concept of pH, though, is abstract and as such is not as important a parameter as understanding the relationship between acidity and balance in the spirit. The importance of the pH concept in relation to chemical reactions will also be covered in part 2.)

Notes: The expression of amounts of components as noted in the table was as posited by Liebmann and Rosenblatt in 1943 and may be expressed in different terms or concentration units today. Some of the chemical compounds listed above are described more fully by Spedding and Jeffery (2015) and Spedding (2017a, b). How the characteristics developed or the parameters changed over time can be seen in the actual papers from the Liebmann research group (Liebmann and Rosenblatt, 1943; Liebmann and Scherl, 1949) and with some facets discussed again in part 2.

It begins with water — then add alcohol — two solvents mix to produce a new solvent system.

Distilled spirits contain the highest concentrations of alcohol of all the alcoholic beverages, yet water (H2O) is still, for most spirits, the dominant solvent component. Water quality is important for producing spirits and especially so for dilution from cask to bottling strength. Yet the properties and importance of both water and alcohol are amazingly overlooked. Most distillers are only interested in whether or not the “right” amount of alcohol is produced during fermentation or is distilled over (free of most congeneric material) ready for bottling (unaged white spirits) or for maturation (aged brown spirits). In typical spirits, 40% alcohol by volume is the norm and after water is the most abundant component present. Yet it is rarely questioned as to why 40% ABV (80 proof) is the most common concentration for spirits on the shelf today, and whether changing this makes any significant difference. The history and the myths here form an interesting story and link to the Russian scientist famous for the development of the modern periodic table, Dmitri Mendeleev (cited in Kuchuk, Shirokova and Golikova, 2012). Some of the physical and chemical reasons are covered below and will help us better understand maturation and the accepted sensory qualities of both unaged and many traditionally aged spirits.

Water and ethanol have their own unique solvent and taste properties which solvate (surround) other substances in specific ways, dependent upon physicochemical properties of all species involved in the mix. Ethanol itself as a solvent confers tactile sensations of warmth or heat and mouthfeel (viscosity), but it also extracts and interacts with many other components to “enhance” the flavor profile. Ethanol has a sensory perception threshold of around 1.4 grams per 100 mL of solution (1.4% w/v – approx. 1.8% ABV or (v/v)). Significantly, it has been discovered that nonvolatile components extracted from oak casks during spirit aging can influence the structure of ethanol-water complexes in distilled spirits (Macatelli, Paterson and Piggott, 2008). This then affects the flavor activity of other more volatile flavor compounds in the product (Spedding and Jeffrey, 2015).

Furthermore, there is a specific mouthfeel theory which states that taste (perception) depends on the organization of the macrostructure of the substance causing the sensory impression. More viscous liquids with more ordered solution macrostructure should taste better (Mazurkiewicz et al., 2009). The solution properties of ethanol and ethanol in water would form a vast topic, but many details have been summarized elsewhere (Parke and Birch, 1999; Henke, Kadlec and Bubnik, 2010). The rest of this article (part 1) will reveal some chemical bonding principles and then a few gems of information regarding the amazing ethanol-water solvent system so important for spirit maturation and to distilled spirits composition.

Water, ethanol, solvent properties and hydrogen bonding

Ethanol and water on their own are both regarded as superior solvents. Water is the universal solvent and is responsible for life on this planet. Both these solvents dissolve many substances, which allows for complex chemistry to occur. Watery solutions are described as aqueous in nature whereas ethanol is representative of an organic solvent. Properties of both rely to varying degrees on a chemical feature known as hydrogen bonding.

The chemistry of hydrogen bonding is detailed in many chemistry text books, with a particularly useful short guide for brewers and distillers being that of Lemke (2012). Hydrogen bonds are formed when negatively charged regions of molecules are attracted to positively charged regions and, while each bond is very weak relatively speaking, many hydrogen bonds occurring together can add considerable stability to solutions and biological systems. For our alcohol beverage purposes, it is noted that hydrogen bonding accounts for the high boiling points of alcohols compared to other organic chemical species; they are held back longer in solution and it takes more energy for them to be released. More significant, though, is the extensive network of hydrogen bonding holding water molecules together. Water is “shaped” into cage-like structures, sometimes called clathrates, which are held together through hydrogen bonding (see Figure 1). The hydrophobic (more water-hating) portion of the ethanol — its tail, if you will — can slip into the cage structure, which means, in simple terms, that a contraction of the total volume occurs upon mixing water and ethanol (Figure 1). The total volume is not simply an additive function of the sum of the water volume and ethanol volume; we have non-volume additive mixing (this will be covered further below). This is one reason, for spirits with low-solids content, the most accurate way of reducing a spirit’s proof is by weight and not volume.

Figure 1: The structure of water and ethanol as a binary solvent and the reason for volume contraction

Ethanol molecules slide into the cage-like water structure and the volume contracts — the final total solution volume is less than the expected sum-total of volumes added.

A final note on hydrogen bonding as a general topic: Hydrogen bonds can form not only between individual water molecules and between individual ethanol molecules in homogenous solvents, but also between ethanol and water molecules (heterogenous solutions, see Figure 2). These types of interactions are called intermolecular hydrogen bonding. If the intermolecular hydrogen bonds form between ethanol molecules, they lead to an increased boiling point of the solution. However, if the intermolecular bonds form between water and ethanol molecules, an increase in water solubility results; the alcohol group (OH) of the ethanol, through hydrogen bond formation, allows it to break into the water lattice and so it is the alcohol functional group itself that promotes the water solubility (the water more easily surrounds or solvates the ethanol). Through this property, water and ethanol are said to be miscible in all proportions, which means complete mixing of the two solvents with no phase separation; this allows for unique solvent properties which change with the relative proportions of ethanol and water present. Other higher-chain-length alcohols (congener alcohols) behave differently. At the microscopic-level pure solvent clusters may form under certain conditions and, more specifically, organic molecules such as the esters do form clusters which affects their volatility in spirits (Conner, Paterson and Piggott, 1994, and much more on this in part 2). Distillers should be aware of this from a maturation strength and aging variable property, from a bottling strength and a taste perspective and for correct dilution operations, as will be demonstrated below.

Figure 2: The intermolecular hydrogen bonding between ethanol molecules and between water and ethanol molecules, which affect ethanol boiling points and the solubility of ethanol in water respectively

Water and ethanol can hydrogen-bond with other components in solution and this, along with the respective amounts of ethanol and water present, will have a big impact on the solvent properties and maturation chemistry: Two apparently simple independent solvent solutions form an intricate binary solvent system! Furthermore, solutes (extracted materials) from the wood can in turn perturb the binary solvent system.

Ethanol and water – studying the solvent systems.

For us to understand how the water-alcohol mixture affects spirit maturation, it is advisable to look at studies regarding the effect of the water-to-ethanol ratio on the mouthfeel of vodka. Later we will see how congeners then impact and alter the mouthfeel and taste of more complex wood-aged and therefore, more flavorful spirits.

Mendeleev (“Mendeleyev” according to Meija, 2009), ethanol-water mixes and viscosity

As alluded to above, one of the biggest myths in the alcohol world is that attributed to 40% ABV alcohol and the reason it is the common denominator for most spirits sold today. To say it’s a Russian thing is not in question: The likely reason Russian vodka is sold at 40% ABV as a standard is most certainly due to the Russian Federation and its rules, regulations and research. Though the setting of this as a standard is often attributed to Dmitri Mendeleev (or Mendeleyev), the Russian chemist to which we owe a debt for creating what has become the modern periodic table of the elements. Unless he was drinking at the age of nine, the standardized 40% alcohol issue and this eminent figure are incompatible; myth dispelled! That said, Mendeleev did in fact run significant research into the physicochemical properties of ethanol solutions later in his life.

Mendeleev noticed that when water and alcohol were mixed there was a rise, then a fall in viscosity (resistance to flow) of the mixtures. Viscosity gives rise to mouthfeel or structure in solutions. This viscosity rise was a surprise to science, as it was to this author when asked to test a competitor vodka for a client. The client was under the impression that an award-winning vodka was “exceptionally smooth” based on the addition of either glycerol or propylene glycol or similar “sweetening” or mouth-coating agents. No such thing! It was likely due to the clean nature of the spirit, the purity of the water and ethanol mix. This leads us to understand that, depending on impurities, ethanol and water when mixed do not behave in an ideal manner; rather the properties of the solution deviate quite substantially from the weighted average of such properties; the expected averages of many of the physicochemical properties of the two individual solutions in this case (Buxton and Hughes, 2013).

The viscosity of aqueous solutions of ethanol changes nonlinearly with concentration. There is a maximum viscosity of solution containing about 47% ABV ethanol, as noted by Mendeleev (see also Figure 3; Mazurkiewicz and Tomasik, 1990; Mazurkiewicz et al., 2007). The viscosity maximum of nearly three times the magnitude of that of water alone is due to an ordering of the components in solution, as we noted above and as mentioned by Buxton and Hughes (2013). Such ordered structures generate “superior mouthfeel.” This led to an interesting quote from the Polish-based Mazurkiewicz group: “That finding may, eventually, explain why commercial vodka has preferably about 45 volume% concentration” (Mazurkiewicz, et al., 2007). Presumably in Poland and Eastern Europe, vodka is sold at 45% ABV strength more regularly than at 40% ABV. Though see below for a different opinion as to the possible “perfect strength for vodka.”

Figure 3. Ethanol-water mixtures and viscosity — the early studies attributed to Mendeleev. Schematic based on data from Mazurkiewicz and Tomasik, 1990; Mazurkiewicz et al., 2007

The viscosity of ethanol-water solutions varies as a function of the relative proportions of water and ethanol (the ethanol volume fraction). There is also a temperature dependency, and such curves can be expressed as a function of alcohol by weight, by volume or as the molar fraction of ethanol in the mixture (Kadlec, Henke and Bubnik, 2010; Khattab et al., 2012). Viscosity affects the mouthfeel of alcohol solutions and the extractive properties of ethanol-water solutions.

Solution to the Mendeleev Challenge. Ethanol-water solution contraction, structure and taste perception

In relation to the structure of ethanol and water composition and mixing, we noted the fact that ethanol and water mixtures are non-volume additive, based on hydration and hydrogen-bonding properties. A neat paper provided by Meija (2009) helps us understand the volume contraction effect first noted by Mendeleev. Mendeleev found the biggest volume contraction to occur upon mixing of ethanol and water when present in the ratio of 1:3. The overall challenge proposed in the title of Meija’s work revolves around the fact that a composition of 1 ethanol + 3 water molecules might be the candidate for the perfect vodka. When taking this ratio in chemical terms (molar quantities in the lingo), Meija carefully works through the math to show that this ratio amounts to 53.9 (54.0)% ABV (Meija, 2009). He then points out that a Japanese rice vodka exists of such alcoholic strength and that it might be representative of the perfect vodka.

So, what does this all mean to modern-day and craft distillers? In a competitive marketplace, moving away from 40% ABV as a “standard” for vodka might possibly have a positive market reach. Though, as noted below, it is difficult to determine taste differences in side-by-side tastings at full-strength alcohol content. Also, restricting vodka production to the U.S. definition rather than a European definition (whereby the taste should be of the raw materials from which the vodka is made) might limit sales potential of distinguishing products. It begs the question as to what impact the allowed addition of a little sugar or citric acid to vodka really makes when it comes to perception over and above a pure alcohol and water product (see TTB ruling 97 below). While part 2 will discuss more barrel-aged products, the European vodka definition allows for flavor from congeners and perhaps interesting nonvolatile components which could play a significant role in quality, style definitions, differentiation of product and consumer taste preference.

From: The TTB ruling (https://www.ttb.gov/rulings/97-1.htm)

“The standard of identity for vodka was promulgated in 1949, in T.D. 5707, 1949-2 C.B. 252. The standard for vodka provided that it was neutral spirits distilled from any material at or above 190 proof, reduced to not more than 110 proof and not less than 80 proof and, after such reduction in proof, so treated as to be without distinctive character, aroma, or taste. Although no explicit definition of the term “distinctive” could be found in the hearing record, the testimony indicates that vodka is to be as tasteless and odorless as possible.

In 1956, Revenue Ruling 56-98, 1956-1 C.B. 811, concluded that citric acid and sugar were not considered to be flavoring ingredients which would materially affect the taste of vodka or change its basic character so long as the sugar did not exceed two-tenths of 1 percent and citric acid was only added in a “trace amount.” The ruling did not quantify “trace amount.” Nevertheless, it is clear that citric acid usage was intended as a smoothing agent to correct objectionable tastes which might result from such things as the water used in reducing the proof, the charcoal used in distillation, or the glass in which packaged. Available information indicates that the use of citric acid from this time until the 1980’s was in the range of approximately 49 to 150 parts per million (ppm). However, starting in the 1980’s, the quantity of citric acid added to vodka increased significantly.

In response to the increased usage of citric acid in vodka, ATF initiated rulemaking to determine whether or not a specific limitation should be established in order to preserve the standard of identify for vodka. The extensive rulemaking history of the citric acid issue is set forth in detail in T.D. ATF-360, 59 FR 67216, (December 29, 1994). In that Treasury decision, ATF determined that a maximum level of citric acid addition of 300 ppm (300 milligrams per liter) was proper before the product became a flavored vodka.”

In addition to maturation, solvent properties and taste perception, the ethanol-water volume contraction effect also affects proofing calculations. In the USA, this is called the “excess volumes of mixing,” and when diluting spirits from barrel to bottling strength, for example, the distiller must take account of the volume contraction effect. This, as a separate topic, has been covered elsewhere (Chen, 2017; Spedding, Weygandt and Linske, 2016) and is mentioned here only for the sake of completeness; volume contraction is thus also an important concept post-maturation.

Structure and structurability

Some more recent and controversial studies have taken place to discern the optimal mix of ethanol and water to give the “smoothest” vodka, for example, with a term called structurability invented to cover this topic. Differences in hydrogen-bonding strength among vodkas led to the discovery of a water-rich hydrate of 1 ethanol molecule to 5.3 (+/-0.1) water molecules in vodka and water-ethanol solutions (I will define this as E1:H5.3 for easier discussion; E, ethanol, H, H20 – water). A now-controversial concept of a structurability parameter (SP) was proposed, which is defined by the concentration or prevalence of the E1:H5.3 hydrate in different vodka samples compared to pure ethanol-water solutions of the same ethanol content. The SP value was noted as quantifying the effect of a variety of trace compounds present in vodka, and, more significantly, it was proposed (and contested) that the E1:H5.3 hydrate and its content are related to the taste perception of vodka. The arguments for the SP concept were provided by Hu, et al. (2010) and the interesting counterarguments by Lachenmeier, Kanteres and Rehm (2011).

The Lachenmeier team pointed out that the E1:H5.3 clusters or complexes were significant at an alcoholic strength of 40% ABV whereas a belief that the most “perfect vodka” should exist with approximately 54% ABV. Interestingly, this concentration is also the value at which the largest volume contraction occurs (as seen above). The Lachenmeier counterarguments were not against the basic idea of structurability but in the sensory perception of differences between vodka brands, and those interested in the complexity of sensory evaluation of high-alcohol-strength beverages should read the Lachenmeier, Kanteres and Rehm (2011) paper to better understand the marketing of their products and read a note on the controversy between the two groups, mentioned here by Hadlington (2010). A review of the wine-tasting controversy might also be in order (Hodgson, 2009) to provide some perspective. Spirits are even more complex to evaluate.

What will become clearer from these structurability studies (in part 2 of this article) is that congeners and other solute species in solution may subtly or grossly affect the solvent structure, and this in turn will greatly impact maturation chemistry. So stay tuned.

Confused yet? 40, 45, 54 – who’s counting? A little knowledge is either a desirable or a dangerous thing!

From the research studies, and commentary above, we see how complex all these studies are leading to different conclusions about the perfect alcohol concentration! For vodka producers 40%, 45% or 54% ABV might be values to play with to see which gives them the satisfaction of producing a marketable, smooth and distinguishable product. So, who is right here? Time and experimentation by the distiller will tell — at least for vodka. The best evidence from above would perhaps lead to 54% ABV as the contender for vodka perfection (with very low or no congeners present) and perhaps even for maturation-strength solvent (see below). But a serious sensory evaluation program, once defined, for looking at such high-strength spirits in an adequate manner or major unbiased consumer acceptance might be needed to prove it. And let us not forget the maximum viscosity at 47% ABV!

But wait, there is more — much more to come. Leading to aging and maturation

Knowing the science and the different theories noted here is as important for the craft distiller as it is for the major players. The studies above pertain to “pure” vodka without any appreciable congeneric constituents. Regardless as to how other volatile or nonvolatile components may affect taste perception, congeners can impact water-ethanol structure, and this most certainly has a significant impact upon the reactions and chemistries taking place during maturation of spirits in wood. This applies to extractions and formation of compounds, and manipulation of the myriad of other components derived from and during the aging process, a topic to which we return in part 2 of this paper, which will include a discussion of studies on maturation carried out with different barrel-strength alcohol concentrations. The vodka studies provide us with the purest solvent base to start looking at maturation chemistry and to begin exploring the expected taste characteristics of an aged and fully matured spirit.

Summary – Part 1

The choice of water-to-ethanol ratios affect the solvent properties and bonding, which dictates the viscosity and the overall structure of ethanol-water clusters. This in turn affects the odor and taste perception of a spirit. The water and ethanol solvent then impacts extraction and solvation of other molecules and the overall volatility and consequent aroma release of components both in the container (barrel, bottle and glass) and the tasters’ mouths. The solutes (the congeners in solution) then exert their effects upon the structure of the water-ethanol solvent. And so on, ad infinitum.

The topic of aging reactions and solvent extraction of components will be the focus of part 2 of this article. Ethanol, water and about 1% total volume of hundreds or thousands of a myriad of other chemical components, both volatile and nonvolatile, form an exceedingly complex physicochemical milieu carrying out a multitude of reaction chemistries. The rapid-maturation teams need to get a full grasp of the chemistry, physics and biochemistry involved in distilled spirits production if they are to beat Mother Nature at her own game and overcome the natural timing of traditional spirit maturation. It really ain’t that easy, folks! And no one yet really understands it, even those who have been looking at the problem for over 80 years! Though the test details from the Schenley group in the 1930s and ‘40s, as detailed here in part 1, will provide us some starting points to further explore the vast literature on spirit maturation. Caveat emptor: 80 years and counting, and we are not there yet!

Yet it is likely that major distillers and research institutes such as the Scotch Whisky Research Institute (SWRI) have uncovered and retain many of the secrets within their organizations. However, this begs the question as to why the major players have not yet addressed, at least publicly, rapid-maturation practices?

“The practice of so called quick-aging was of some importance during the period immediately following the prohibition period, which brought about an almost complete exhaustion of aged whisky.”

“The special treatments then applied (for rapid maturation noted from the 1940s) have since been completely abandoned by practically all distillers.” (Liebmann and Scherl, 1949).

One must ask why the practice was abandoned and whether it was based on the need for tradition to be upheld or because the product was inferior? This question and more as to how maturation of spirits takes place, based on solvent and solute chemistry, along with a few real clues as to how to possibly and realistically speed things up a little will be covered next time.

Gary Spedding

Spedding is a brewing and distilling analytical chemist and biochemist with a special interest in the origins and development of beverage flavor and in the sensory evaluation of beer and spirits. His company, Brewing and Distilling Analytical Services (BDAS, LLC), a triple TTB certified laboratory, was founded in 2002 as an unbiased and dedicated facility for testing alcohol-containing beverages and beverage raw materials.

Brewing and Distilling Analytical Services, LLC

Lexington, KY

www.alcbevtesting.com

References

Buxton, I. and Hughes, P.S. (2013). The Science and Commerce of Whisky. Royal Society of Chemists (RSC Press).

Chen, F. (2017). Partial Molar Volume: Its Application in the Brewery and Distillery for Volume Contraction Calculations and Alcohol Concentration Determination. Artisan Spirit, Issue 18, Spring 2017; 80–84.

Conner, J. M., Paterson, A. and Piggott, J. R. (1994). Agglomeration of Ethyl Esters in Model Spirit Solutions and Malt Whiskies. J. Sci. Food Agric. 66; 45–53.

Hadlington, S. (2010). Chemistry World: Vodka taste test tiff. https://www.chemistryworld.com/news/vodka-taste-test-tiff/3004252.article (last accessed, June 2017).

Henke, S., Kadlec, P. and Bubnik, Z. (2010). Physico-chemical properties of ethanol — Compilation of existing data. Journal of Food Engineering. 99; 497–504.

Hodgson, R. T. (2009). How Expert are “Expert” Wine Judges? Journal of Wine Economics. Vol 4 (2); 233–241.

Hu, N., Wu, D., Cross, K., Burikov, S., Dolenko, T., Patsaeva, S. and Schaefer, D.W. (2010). Structurability: A Collective Measure of the Structural Differences in Vodkas. J. Agric. Food Chem. 58 (12); 7394–7401.

Kadlec, P., Henke, S. and Bubnik, Z. (2010). Properties of ethanol and ethanol-water solutions – Tables and Equations. Sugar Industry/Zuckerindustrie 135(10); 607–613.

Khattab, I. S., Bandarkar, F., Fakhree, M. A. A. and Jouyban, A. (2012). Density, viscosity, and surface tension of water+ethanol mixtures from 293 to 323 K. Korean J. Chem. Eng. 29(6); 812–817.

Kuchuk, V.I., Shirokova, I. Yu, and Golikova, E.V. (2012). Physicochemical Properties of Water-Alcohol Mixtures of a Homological Series of Lower Aliphatic Alcohols. Glass Physics and Chemistry. 38(5); 460–465.

Lachenmeier, D. W., Kanteres, F. and Rehm, J. (2011). Is It Possible to Distinguish Vodka by Taste? Comment on Structurability: A Collective Measure of the Structural Differences in Vodkas. J. Agric. Food Chem. 59; 464–465.

Lemke, T. L. (2012). Review of Organic Functional Groups: Introduction to Medicinal and Organic Chemistry (Fifth ed.). Lippincott Williams & Wilkins/Wolters Kluwer.

Liebmann, A.J. and Rosenblatt, M. (1943). Changes in Whisky While Maturing. Industrial and Engineering Chemistry. 35 (9); 994–1002.

Liebmann, A.J. and Scherl, B. (1949). Changes in Whisky While Maturing. Industrial and Engineering Chemistry. 41 (3); 534–543.

Macatelli, M., Paterson, A. and Piggott, J.R. (2008). Spirit flavor release under mouth conditions. In: Distilled Spirits: Production, Technology and innovation. (J.H. Bryce, J.R. Piggott and G.G. Stewart, Eds.) Nottingham University Press. Chapter 22; 151–158.

Mazurkiewicz, J. and Tomasik, P. (1990). Viscosity and Dielectric Properties of Liquid Binary Mixtures. J. Phys. Org. Chem. 3; 493–502.

Mazurkiewicz, J., Baranowska, H.M., Achremowicz, B, and Tomasik, P. (2009). Physicochemical Evaluation of the Organoleptic Quality of Flavored Vodkas. Electronic Journal of Polish Agricultural Universities (EJPAU). 12(3): Article #06; 1–12.

Mazurkiewicz, J., Baranowska, H.M., Wojtasik, M. and Tomasik, P. (2007). Macrostructure of Aqueous Solutions of Ethanol and Its Implications. Electronic Journal of Polish Agricultural Universities (EJPAU). 10(2): Article #17; 1–9.

McLafferty, C. (2016). The scientific arms race to age our whiskey. https://arstechnica.com/science/2016/07/the-scientific-arms-race-to-age-our-whiskey/ (last accessed June 2017).

Parke, S. A. and Birch, G.G. (1999). Solution properties of ethanol in water. Food Chemistry. 67; 241–246.

Spedding, G. (2017a). Toasting My Spirits: Maillard and the Incredible Reactions He Uncovered in 1912. Part 1 — The Chemistry. Artisan Spirit, Issue 18, Spring 2017; 98–102.

Spedding, G. (2017b). Toasting My Spirits: Maillard and the Incredible Reactions He Uncovered in 1912. Part 2 — The Maillard Reaction and Distilled Spirits Production. Artisan Spirit, Issue 19, Summer 2017; 65–69.

Spedding, G. and Jeffery, J. (2015). Distilled Spirits and Key Flavors: Smelling Roses, Fruit, Stinky Feet and Much More in My Glass. Artisan Spirit. 12, Fall 2015; 53–58.

Spedding, G., Weygandt, A. and Linske, M. (2016). Alcohol Dilution Practices for Distillers. Artisan Spirit Issue 14, Spring 2016; 65–70.