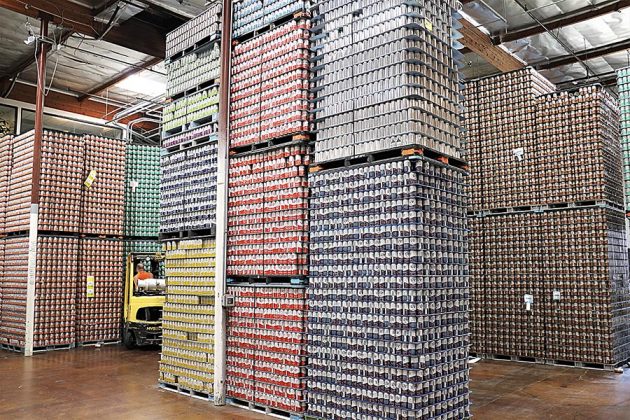

Step into the cavernous warehouse of Cutwater Spirits — located in the Miramar neighborhood of San Diego, an area first made famous as the actual site of the Top Gun program at Marine Corps Air Station Miramar before becoming a hub for a cohort of local brewers and distilleries — and prepare to be awed by its mammoth multicolored towers of cans soaring to the ceiling.

It’s a temple and a testament to the power of the RTD, and with some simple back of the envelope math — if there are 60 24-can cases to a pallet, with three or four pallets piled atop one another in dozens upon dozens of these staggering stacks — you can easily estimate there being hundreds of thousands of cans back there. Business is booming, and surely you’ve heard, after all, that it was a beer conglomerate that purchased Cutwater, when AB InBev made its first foray into spirits in early 2019.

While Cutwater’s spirits themselves are highly touted — and deservedly, as I can attest; several award-winning Cutwater pours have passed my lips during blind tasting at the American Distilling Institute’s annual judging event — make no mistake about it, ABI was ready to buy because of Cutwater’s ready to drink.

From Beer to Spirits & Back Again

Stroll through the main entrance of Cutwater Spirits, though, and you don’t see a skyline of RTDs welcoming you within. No, you see the glass-encased 35-foot tall Vendome column still the distillery keeps constantly firing away. Spirits production is serious business at Cutwater, and it always has been. That traces back to the distillery’s roots as a piece of Ballast Point, and yes, even precedes Ballast Point’s billion-dollar acquisition by Constellation Brands.

The distillery is also home to a full restaurant, bar and de facto tasting room that would be the envy of almost every other distillery in the country if they caught a glimpse of it. The building’s sharp-edged architecture, flowing water and various stylistic and design elements call to mind the naval inspiration of its name. Beyond all that beautiful Vendome copper, visitors move past a wall of awards on their way inside, likely for a meal and a few drinks, and oblivious to all the action taking place in the other half of the building: the state of the art laboratory, an array of stills, the canning and bottling lines noisily performing their countless and thankless tasks, the worker bees buzzing around pallet after pallet.

“We developed what was then Ballast Point Spirits within the brewery, and we already had all this stuff on order,” says Yuseff Cherney, Cutwater’s founder and master distiller, as he waves his arm toward the current distillery. Cherney, of course, was also the former COO of Ballast Point. “I was the first employee at Ballast Point, about 28 years ago now,” he says.

Back then, he was focusing on home brewing equipment and sales. Cherney’s initial forays into the world of distillation started small, about a dozen years ago

Within the stillhouse today, there are half a dozen different toys to play with. There’s the stainless steel gin still with botanical basket, which is a remnant of those first experiments. An odorous lesson was learned when a first batch of whiskey ran through that stainless steel, sans copper, all those years ago. There’s also a tiny experimental setup, an alembic-head pot, a hybrid rig that’s now devoted to rum production and the doubler attached to that two-foot diameter Vendome.

Whiskey maturation is done entirely in full-size, heavy char 53-gallon barrels, of which they currently have about 3,000 in a warehouse across the street from the main production facility. The whiskey portfolio currently includes Devil’s Share Bourbon, made from a high barley wheated mashbill, and Devil’s Share malt whiskey. Blended bourbon and rye are also available under the Black Skimmer name. This line of sourced spirits also provides the base for the RTDs, as even with all the distillation firepower they have under one roof it would be impossible to keep up with production demands for the aged spirits needed there.

The distillery uses the same aforementioned new barrels for its rum, which is made from a base of evaporated cane. “There’s more pronounced fruit characteristics than molasses,” Cherney says. “Molasses was just never it for me.” Products in the Three Sheets rum line include white, barrel-aged and cask strength varieties.

Cane sugar is further used as the sweetener for the entire portfolio of RTDs, as opposed to high fructose corn syrup or anything of the sort. It’s a healthier choice, but also one that was rooted originally in taste preferences, based on Cherney recalling the delights of a rum and cola mixed with Mexican Coke.

There’s vodka, gin and barrel-aged gin, reposado tequila brought in from Mexico and aged in the distillery’s whiskey barrels and even a tiki cocktail-inspired lineup of rums dubbed Bali Hai. “Part of me is a purist, but part of me is like, let’s have some fun!” Cherney says. “We’re huge tiki fans.”

The breadth of what they make is astonishing, with roughly 17 bottled spirits alongside 17 different RTDs, plus nonalcoholic offerings. “That’s what’s oddly unique about us,” Cherney says.

The distillery also houses a full high-tech sensory lab. They evaluate everything they produce and source, work on new blends, test out wacky distillate and RTD flavors and generally see what type of trouble they can get into. “It’s a play to my geekiness,” Cherney says. “We’re trying to fingerprint not only what we make here but also what we’re bringing in.”

The lab and the rigorous processes and devotion to quality at every step also ensure there’s a why for every what. “I’m a philosophy major, so my thought process is always, ‘Why are we doing this? Is there a reason? Is that reason based in a tradition or a fact?’” Cherney ponders.

With his roots in the world of beer, it’s no surprise that many of those whys begin there. “From the start, coming from a brewing background I applied a lot of brewery technique,” Cherney says. That includes the use of 2-row brewers malt and a lower, slower fermentation process. Cutwater ferments at around 70 degrees, prolonging the cycle to between five and six days, as opposed to a 90-degree fermentation that could wrap up in two or three days.

Of course, Cutwater doesn’t make beer, but in a way Cherney is back to where he started, under the stewardship of a larger beer company, similarly to how the distillery itself was born out of Ballast Point.

Adjusting to the AB InBev Acquisition

The move from craft distillery under your full control to being but one cog within a much larger operation always presents a challenge. It occurred to me that may be even more the case here, with a spirits company being folded into a beer powerhouse. “You hit the nail on the head with that,” Cherney says in response when I actually levied the question. On the other hand, that’s the part of the industry Cherney comes from, and he’s also been through the acquisition process before.

“The nice thing about this acquisition is that there really hasn’t been any change to my role,” Cherney says. “My role is innovation, product development, a little bit with engineering, and I’m still micromanaging a bit, but we have a team of folks doing everything. One of the main points of a successful acquisition is the retention of founders, and [ABI] really stressed that and their belief in that. It’s also about having complementary partnerships, and being able to develop synergy.”

“ABI is this giant company, and for them to buy us as their first spirits venture in the US, it’s a huge accolade,” Cherney continues. “It felt like winning an award.”

Others might say it looks more like luckily managing to hit the lottery — not once, but twice! — rather than winning an award. “Listen, people talk about lightning striking twice, but hopefully it’s not coincidental, I’d say there’s some skill involved there,” Cherney says. “Is there luck involved, too? Sure! I’d rather be lucky than good.”

He also doesn’t see eye-to-eye with the backlash he’s occasionally heard, whether from consumers or even others in the craft space. “There’s this intimate connection with customers in beer and spirits, and there’s a small percentage of people who feel like they’re betrayed in some way,” Cherney admits. “A lot of people are aggressively opposed to acquisitions, but the flip side is the struggle and failure of any type of business. If I came to someone not in the spirits industry and told them I worked my whole life and had an opportunity to sell my company to the biggest player in the world, would they pat my back or call me an asshole?”

Of course, it was never about cashing out, but hopefully both sides of the deal come away happy. For Cutwater, they now have the full and immense logistical support from the ABI mothership to grease the wheels of distribution, marketing and expansion. From ABI’s side of the fence, they get to try out this whole distillation thing while bringing in a proven commodity within the quickly growing RTD space that may be able to siphon off a slice of the wildly and exponentially growing hard seltzer market, too.

Just, please, don’t call them hard seltzer.

“The huge difference with us is that we make this shit here!” an exasperated Cherney insists. “Our products differ from hard seltzer because we actually have spirit in there!” He’s preaching to the choir with this audience, surely.