Young distilleries need all the help they can get when it comes to getting their brand out and in front of customers. Most people involved in this industry know it’s a tough game to get into. Issues of limited distribution, crowded shelves and cash flow have squashed many a hopeful dream. While there are more than a few ways to generate extra revenue and increase brand awareness, few are as valuable as cocktail bitters. Cocktail bitters, you say? That’s right, those small dusty bottles might just be the product your distillery needs.

Bitters are essentially a strong herbal extract. They have coexisted with distilled spirits for centuries and are inseparably linked to them through the advent of the cocktail. Prior to this, many a fortune was made on these extracts as they were touted as cure-alls for almost any ailment. During Prohibition, they served to mask the flavor of rancid bootleg liquor. During the mid-20th century, bitters saw a long period of dormancy, but are currently experiencing a sustained resurgence. In modern times, bitters serve to enhance rather than mask flavors of craft spirits. These days, people shop for bitters alone, and there are retailers in the USA that are dedicated to selling exclusively bitters. Sadly, many distillers overlook this product as a potential offering. In this article, I will argue that most distillers should produce their own line of cocktail bitters as a means of increasing revenue and brand awareness.

Bitters are food

The Alcohol and Tobacco Tax and Trade Bureau (TTB) considers cocktail bitters to be a food flavoring extract. When produced properly, the TTB National Laboratory will test formulas and deem cocktail bitters “unfit for beverage use.” This confusing distinction takes bitters out of the beverage realm entirely and qualifies them as a food product. This distinction is one of the key reasons why bitters are so beneficial for a distillery to produce. As a food product, bitters qualify for drawback of more than 90% of excise tax paid on any spirits used in their formulation. The cost savings gained from having excise tax returned goes a long way toward making bitters a financially viable product to bring to market.

Another benefit to their distinction as food is that you are allowed to sell online or directly to customers. If your distillery exists in one of the remaining U.S. states with laws against direct-to-consumer spirit sales, this could be a game-changer to a young distillery as you are working to generate revenue while securing distribution for your spirits.

Broaden your market

It is no secret that distilleries, with a few exceptions, are limited to selling through on-premise establishments and retailers with liquor licenses. Wouldn’t it be nice to have product located in all the locations where your target customers shop, including small grocery stores and gift shops? You are legally allowed to sell a properly registered and produced bitters in these places. This opens up your brand to markets that your spirits would never be allowed to enter.

Increasing your visibility in high quality, non-liquor-oriented retailers goes a long way to building brand trust and recognition. Furthermore, the customers that try and like your bitters will be willing and eager to try your spirits when they come across them.

Small bottle, small investment

Most operating distilleries already own 80–90 percent of the equipment needed to produce bitters. If you are a gin distiller, you are even closer as you probably stock most of the botanicals used in bitters. With a small investment in a few extra ingredients, bottles, some extra design, printing and a little time, a bitters is an entirely realistic product for a distiller to create.

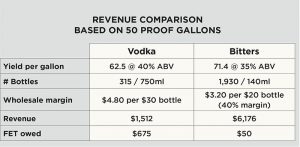

Revenue Comparison

As a hypothetical example, let’s compare 50 proof gallons of vodka and 50 proof gallons of bitters and see how they differ in revenue. These are estimates meant to give you an idea for revenue potential.

How to get started

Producing a line of bitters starts with developing a quality product. This is one of the more challenging aspects of this venture. Producing bitters basically involves macerating herbs in alcohol for a certain period of time.

Sounds simple, right? It isn’t.

Once you have your recipe and process down, producing bitters does become quite straightforward, but you will need to invest some time in getting your recipes dialed in. You will find that different botanicals extract at different rates based on alcohol percentage, temperature and time. Plan to experiment in small batches and make minor changes until you land on the right recipe and process. When I started Five by Five Tonics, I had dozens of mason jars lining my hallway shelves at one point, each with a different variation on one recipe. Every morning I would swirl each jar and taste them all.

A good starting point is to create a simple version of an aromatic bitters. This will get you familiar with the common botanicals used in bitters and how they “behave” in extraction. It is easy to mess up recipes like this, so patience is rewarded. Once you are comfortable with common botanicals, then you can branch out from there.

The second consideration is how to strategically brand the product. There are two options here. The first is to brand the bitters the same way as your spirits and the second is to brand them completely differently. There are pros and cons to each, but I suggest the former for the simple reason that it will engender brand recognition that translates to the products you ultimately hope to sell: your spirits. You don’t necessarily need to make the bitters bottles identical miniature versions of a spirits bottle, but some similarity goes a long way in drawing connections to the rest of your products.

A few considerations

I have spent this entire article painting a picture of the relative ease in producing a line of bitters. There are, however, a few considerations that you will need to keep in mind as a distillery when going into producing bitters. First off, if you are producing food, you need to register with the state-level health department at the least. If you plan to offer any products for purchase and consumption on-site, you’ll likely need to get the county or city health department involved. This is all generally very simple, but I have found that most distilleries do not involve the health department in their facility.

Secondly, while I did say that you already own most of the equipment for bitters production, you might want to consider eventually keeping separate equipment for this effort. Bitters come from some very strong post-distillation botanical flavors, and there is really no way to guarantee those flavors will not leach into other spirits. This obviously applies to any wood vessel, but should be considered for stainless and glass as well as any bottling equipment.

Aside from these considerations, there should be no reason that any operating DSP couldn’t produce a line of bitters with its own signature flavor that both increases revenue and builds brand recognition and loyalty. A small investment up front might go a long way to broadening your brand’s reach and appeal.

Simple Aromatic Bitters Recipe

1,000ml grain neutral spirits (35% ABV) 10g fennel

20g gentian root 10g cinnamon

20g clove 10g black pepper

20g star anise Sugar to taste

Place all botanicals and alcohol in a sealed mason jar for up to two weeks, depending on temperature. Taste and agitate daily until desired flavor is achieved. Extraction may vary, so consider adding botanicals individually to get a sense for how quickly they release flavors.