Lost Spirits Distillery is a deceptive name. It’s a place less about making alcohol and more about waking an industry from a centuries old stupor. To say there has been no innovation since our earliest forbears turned grapes into wine and then into spirits would be hyper-simplistic; and yet, when it comes to technologies for making liquor, advances have been slow to come and primarily limited to refinements of the process. Differences between the modern and ancient are a matter of degree.

There is a certain dignity to this: The simplicity of a tradition, which allows for such grand transformation—one seemingly impossible to improve on—instilling a sacred purity to the process: It elevates the trade into an art form. And therein lies the rub. Innovation is rarely welcome, and anything truly transformative is considered blasphemy; which is understandable yet ironic. Distillation as we know it was born from minds burning with revolutionary thoughts and dangerous ideas. Shouldn’t this legacy be honoured by keeping that flame of curiosity alive? Perhaps there’s a middle ground; a town “big enough for the both of us”; a way by which the lexicon of distillation can expand, with room for the traditionalist as well as the vanguard.

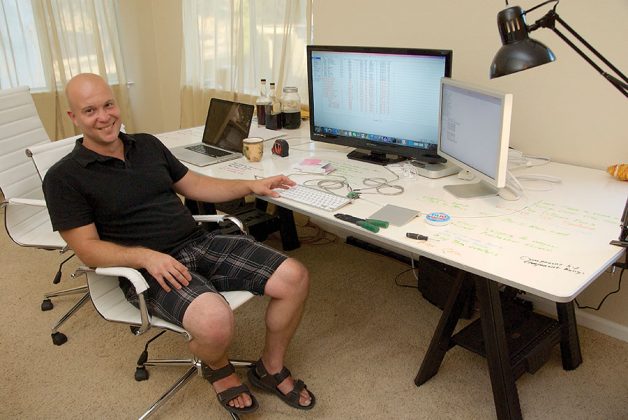

Among those modern visionaries is Bryan Davis, co-owner and founding partner of Lost Spirits Distillery. To some, he is Bacchus incarnate; to others, a Dr. Frankenstein without the MD. Regardless who is right, what he’s done is certainly impressive.

The seeds of sedition sprouted when Davis and his partner, Joanne Haruta, arrived in Las Vegas, after spending a few years in Spain making absinthe. The green fairy had lost its novelty factor, and facing a future feeding the few remaining hardcore devotees wasn’t all that inspiring. He took a step back and looked at the distillery business, then quickly realized that the singular defining factor of any prized liquor resided in its aging. Time in the barrel was where lead turned to gold. He saw two choices: barrel his liquor, wait 12 years, and trust that the final product would turn out as he hoped, or try to cheat Father Time by fooling Mother Nature.

Davis chose the path of the alchemist. He focused on the chemical building blocks that create the long-chain esters, which gives liquors their most desirable flavors. And in the case of aged spirits, the magic came down to two things: extraction and esterification (esterification is the chemical reaction through which phenols and acids bind to alcohols, forming esters; whereas extraction is the method whereby elements in the barrel are pulled out of the oak and brought into the mix). But, the question remained, how exactly do these two work together to produce such a wide range of complex flavors that vary so profoundly with age? How much came from the barrel, and how much could be attributed to the distillate itself? Most importantly, how does the specific tick-tock of time factor into the equation? Or, as Davis would say, how could time be accelerated without compromising the process?

The most comprehensive study he found that even hinted of answers had been published 107 years ago by the American Chemical Society. Beyond this, Davis essentially was on his own. Having had no formal training in science was probably a good thing; he didn’t know what he didn’t know, so he pushed forward, oblivious to any earlier postulations made by learned naysayers. One of the first things he discovered was the significant role that precursor acids, carried over from fermentation, played in the beginning stages of maturation. In the life of a spirit, day one to year seven is a time when the interaction between these acids and the alcohols sitting in the barrel produced the bulk of the short-chained esters; volatile esters responsible for the fruity and aromatic flavours found in an aged spirit; the implication of which brought with it another surprise. Since a barrel’s first seven years were fundamentally spent serving as an incubation tank for combining the precursor acids to alcohol, theories of increasing surface area of the oak or forcing a more vigorous oxygenation were flawed. Premature extraction created a chemical imbalance that interfered with the initial esterification. For any accelerated-aging technique to work, both processes had to occur in lockstep.

“Part of the reason the spirits aging process has proven so difficult to accelerate is because the extraction process does not appear to be linear. In other words, the addition of more oak surface area seems to extract more of the first compounds to leach from the oak as opposed to a proportionate mixture of the compounds extracted over time,” Davis wrote in a white paper, available on the Lost Spirits website.

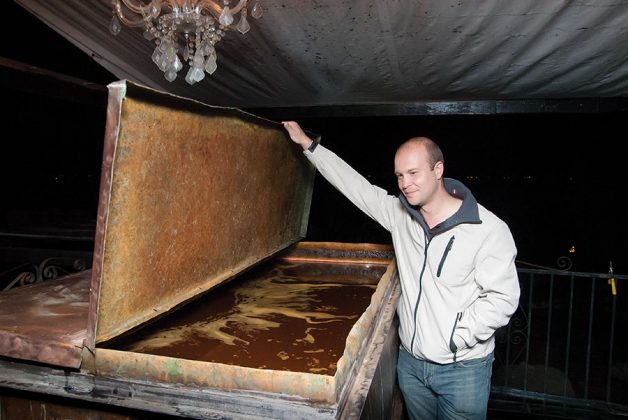

Within two years, Davis had an esterification reactor chugging away in his kitchen, which was a feat unto itself. Yet, it was only the first of many steps towards a functional comprehension of oak-matured distilled spirits which, as

Davis himself admitted, is “one of the least well-understood consumer products in the world.”

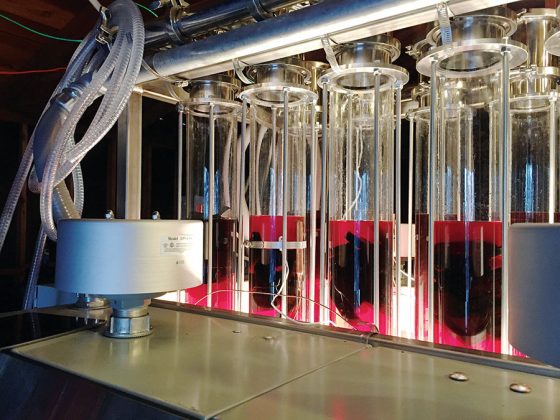

“The reaction is a three- or four-phase process, depending on your final goal,” said Davis. “One of our reactors is really three or four, daisy chained together, depending on your configuration.”

“The first reactor in the daisy chain is an esterfication reactor, which takes all the raw acids from the spirit and it forces them to bind to the alcohol,” said Davis. “It takes the raw stuff that you got in your white spirit and turns them from rancid to fruity. It basically only makes only one thing:—short-chained carboxylic esters.”

The next problem posed was how to deal with extraction in a way that did not hinder esterification. Extraction on its own is easier to recreate and accelerate than esterification but, when done in combination with esterfication, became an ordeal. Davis had to figure out a method to extract the necessary aldehydes, phenols and acids from the oak. He also needed the process to be isolated and coordinated with the end of the first esterification. Through trial and error, and after many pages torn from the calendar on his wall, Davis eventually created a method whereby particles were energized to break the requisite polymers free from the wood and into the distilled spirit.

“In stage two, which is the really cool part, what we do is fire protons at the wood,” said Davis. He set up a series of lights that mimic sunlight—three times the concentration of light you would find at the equator at noon on the equinox. “The polymers get attacked way more efficiently under the high intensity light than in sunlight,” said Davis. “When the polymer shatters, it gives you everything in less than two days that it would have given you during twenty years

in the barrel.”

In phase two, the wood breaks down to give new medium-chain carboxylic acids, acetyl, phenolic acids and phenolic aldehydes. The extracted acids then bind with the alcohols to form medium-chained esters—the semi-volatile esters that are key to earthy and nutty tastes and mid-palate fruity notes.

The third phase is a second esterification during which the short-chained esters (created during the first esterification) and the medium-chained esters (formed during the extraction process) bind to alcohols to form long-chained esters—the esters responsible for the floral, sweet honey, and tobacco flavors found in the most coveted spirits. A pleasant side-effect of this second esterification is that certain precursor acids that normally produced off-flavors became pleasant, diminished or vanished entirely; as Davis put it, “turning rancid into fruity again.”

In short, what Davis had done was build a mechanism that, in a mere six days, produced a chemical facsimile of a 20-year-old rum.

It is important to note that Davis didn’t work locked up and alone in a cellar somewhere; every step he took was heavily guided by detailed scientific analysis. Davis created a chromatogram library of aged rums—something previously only available for malt whiskey—from which to compare his creations to classic rums. Every experiment was scrutinized using the objective and impersonal eye of gas chromatography—mass spectroscopy; a process that also revealed the addition of sugar and/or prune juice in some of the highly coveted rums. His goal was to understand the maturation process in order to replicate the outcome more efficiently.

Since announcing the Lost Spirits process in April, Davis has taken 65 orders for his Thea One Reactor and has secured venture capital to have the machines tooled for him by a major pharmaceutical supplier. Unlike some distillers who lock their proprietary process around a cloak of secrecy, Davis intends to unleash his now-patented Frankenstein creation on the rest of the distilling community, or at least, the willing. Whether his final creation will win us all over, whether it will successfully de-extinct such long-lost spirits like Wray and Nephew’s Seventeen Year-Old Rum, or some tiny unanticipated subtlety will keep his six-day-old liquors from truly replicating the Beethovian grandeur of a 20-year-old rum; whether the distilling community will praise him or come back with pitchforks, is all yet to be determined, and an answer even Davis won’t be able to accelerate. However, it is not hard to believe that somewhere, the original alchemists are looking down, smiling, knowing that finally the game is once again afoot.

FINAL NOTE

On the Lost Spirits Distillery website, there are three papers detailing the processes he used as well as his final findings. They were co-written with professors at UC Davis, and can be found at: www.lostspirits.net/#!science-/c1kb3.