Being an aficionado of the Slow Food Movement since the beginning, I would like to add another antidote to the tyranny of the fast food industry and the frenzied pace of modern culture.

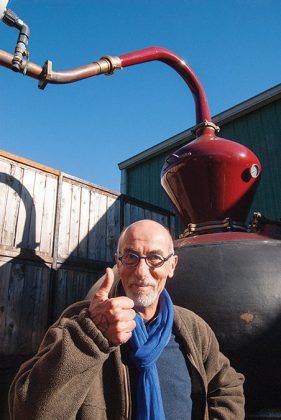

Slow Distillation

By using ancestral methods of distillation, when time was not such a pressing issue, one would conduct the distillation at a slow pace to be able to separate with precision the different components, to make clean cuts and to respect the temperature during the gathering of the distillates. With today’s hurried approach, many of these parameters are undervalued or even ignored by craft distillers.

For centuries, distillers passed down to successive generations the nuances of creating flavors from the materials available. These artisans created good spirits before thermometers were invented, not understanding the molecular difference between methanol and ethanol or even knowing the names and vapor temperatures of any of the compounds they were separating.

Distillers must listen to a spirit coming off the still in order to understand how much time in the barrel it will take for flavors to blossom and come to full beauty. Little thought or teaching is currently given to the understanding of how to ferment and distill a spirit when one intends to age it for 4, 12, or even 20 years. The rapidly made products often seen today have a limited appeal to consumers who pay attention to what they are drinking. This commodity approach to spirits production may produce a few small fortunes, but will no doubt produce many more inferior products that will need the presence of a bartender to bring to full flavor.

Slow Maturation

By learning from the experience of generations of cellar masters, one realizes that time and patience are factors you cannot fully control, except by having proper levels of humidity and temperature in your cellar. Forcing the aging process by raising temperatures and using smaller barrels (which are usually made of wood of lesser quality) to obtain faster extraction often results in harsh and excessive tannins, which will take many years for the spirit to digest. Balance and harmony are reached by knowing the pace of transformations occurring in the barrels through the periods of oxidation and of rest. This is necessary and elementary to have a quality product.

In the modern distillery age, the distiller is more likely to be flooded with information about saturating their spirit quickly with wood extract to make it marketable than they are presented with information about how to slowly nurture barrels into producing a supple, round, full flavor from the depth of years. Consequently, today’s distiller is more likely to toss their precious water of life into barrels and forget about it for two years, or for six years, and with little regard to maintaining proper maturation conditions, like a cake baking in the oven for a specified amount of time.

By making abstraction of, or simply ignoring, either slow distillation or slow maturation, these craftsmen limit themselves in creating true artisan products. The consequences are not always obvious in the short term but appear later, resulting in regrets and disappointments. Remember: In this long journey, you cannot go back in time; you have to live with your decisions—good or bad.

Can a rum or whiskey, after being stored in a barrel for only a year, truly be called mature or aged when, at the same time, a brandy, Cognac, Calvados or Scotch (and many other spirits) have to rest at least 2.5 years in oak (which is still quite young) to get the due appellation?

I urge the distiller to slow down, take a mindful approach and join in the sharing of small details that, when combined together, have the effect of creating a spirit that can be savored.

At the beginning of this revolution—which will go on for years, decades and centuries—the foundation can be laid so that craft will become the designation of quality.

Rules should be put in place—by the craft distilling industry itself—to establish control over the declaration and on the labels for the consumer’s good. The Europeans have put a strict system in place that could be used as an example to make designations fair for everyone. Such a system will also serve to elevate quality, and reinforce appellations and sub-appellations that will be created in the near future.