In 2007, fifteen curious classmates with one shared goal — to learn the art of commercial craft distilling — attended the first American Distilling Institute (ADI) Hands-on Whiskey Distilling Workshop at Stillwater Spirits in Petaluma, California.

Over the next few years, the whiskey workshops expanded into offerings of rum, brandy, gin, vodka and botanical spirits, as well as master classes in brandy, apple brandy, sensory analysis and blending.

Workshop graduates have gone on to found their own distilleries, for instance, Colin Keegan of Santa Fe Spirits, Wes Henderson of Angel’s Envy, David Woods of Wiggly Bridge Distillery, Stephen Paul of Hamilton Distillers and Kirby Kallas-Lewis of OOLA Distillery. Others, like Paul Werni of 45th Parallel Distillery and Tom Burkleaux of New Deal Distillery, had already launched their own distilleries and sought information on how best to improve quality control, market new products, navigate regulations and network with peers in similar shoes. Many of those graduates even ended up hosting workshops of their own, continuing this pay-it-forward culture that strengthens the American craft-distilling community.

2018 marks the 15th anniversary of ADI beginning its mission to promote and defend the art and enterprise of craft distilling in the U.S., which has grown from a mere 40 distilleries in 2003 and, with craft distilleries opening at a rate of about two per working day, should pass 1,500 working craft distilleries by year’s end.

The great late poet Maya Angelou once said, “You can’t really know where you are going until you know where you have been.”

To that end, for a better sense of our industry’s future, we reached out to a few experienced distillers — an early generation of craft spirit-makers, if you will — to see if we could determine how far the industry has come by understanding some of their humble beginnings, early challenges, lessons learned and secrets to success.

Meet the Graduates

Paul A. Werni,

45th Parallel Spirits, LLC

New Richmond, WI

45thparalleldistillery.com

At the age of 39, Paul Werni was looking for a change. In 2005, with a passion for building and being creative, it was craft distilling that drew him in. Today he’s the founder and president of Wisconsin’s 45th Parallel Spirits, producing a range of high-quality vodkas, gins, whiskeys and citrus spirits like limoncello and orangecello. However, his path to the still hasn’t always been a smooth one.

In the beginning, “information was not available,” Werni said. “There were very few distilleries to work at and learn from. Cash flow was difficult, and there were few supplier options when it came to glassware and equipment for us smaller operations back then.”

To overcome this challenge, Werni set out to build a network of knowledgeable peers he could pepper with questions, which coupled well with a willingness to learn from trial and error. The ADI Hands-on Distilling Workshops played a pivotal role in this.

“I made important early contacts,” Werni said. “These contacts were other distillers in the same boat as me, and those relationships gave us the ability to contact each other and solve problems. The resource directory is extremely helpful, too.”

To this day, Werni still remembers who he met at the conference workshop early on. “Don Poffenroth (Dry Fly Distilling), Nick Quint (Yahara Bay Distillers), Joe Henry (J. Henry & Sons Distillery), Guy Rehorst (Great Lakes Distilling) and Brian McKenzie (Finger Lakes Distilling),” Werni said. “And at the last ADI conference I sat in on the FDA workshop. Three weeks later the FDA showed up at my facility for an inspection, and I knew just what to anticipate from a federal inspection.”

Today, with Werni at the helm, 45th Parallel Spirits continues to show consistent year-over-year growth in both physical size and production capacity, as well as professionalism.

We asked each distiller what advice he had for anyone looking to enter the business. Werni said:

“Start small, get good at it before expanding and don’t take shortcuts. Pay attention to details and the numbers, make sure you are in it for the right reasons and most importantly maintain patience. Attend more than one distilling class or workshop and attend an ADI conference, because the trade show is a good place to find supplier options.”

Colin Keegan, Santa Fe Spirits

Santa Fe, NM | santafespirits.com

Some might say Colin Keegan took the “long way” to arrive at the realization he would spend the rest of his life trying to become a pre-eminent artisan distiller in the Southwest. Not because he waited to open Santa Fe Spirits in 2010 at the age of 44 after completing a full career as an architect; midlife crises pluck plenty of distillers from the general population each year, and we’ve heard that story before. It’s because of the physical distance he traveled to get here — England to the British Virgin Islands to the American Southwest.

When the economy crashed in 2009, Keegan, a whiskey aficionado from the United Kingdom, retired from a career in building things for clients to embark on a project of his own — building a distillery. The home he’d built with his wife on a mature apple orchard in the farmlands of Tesuque, NM, yielded an abundance of apple cider annually and this was ulti mately the inspiration for his first spirit: apple brandy.

“I had an apple orchard with too many apples,” said Keegan. “So I made apple brandy, and the business grew from there.”

For a better understanding of the business early on, Keegan attended an ADI convention. “I met a bunch of fine folks,” he said. “And I decided these were the people I wanted to do business with. Probably because there were no distributors there!”

It was this initial band of brothers that helped Keegan overcome one of his biggest initial challenges — a state that didn’t know what to do with him.

“We are in Santa Fe, New Mexico, and the state had no such licensing for a distillery. Their advice was to apply for a restaurant license because it’s the closest thing we had.”

With a tenacity and stubborn determination, Keegan continued to develop his skills in the distillery, and from peers and industry veterans like Jordan Via, he swapped stories and problem-solved with other distillers starting out on the same journey.

“ADI introduced me to peers, information suppliers, and ultimately some of my best friends.”

Today, Santa Fe Spirits is looking to extend its Colkegan Single Malt Whiskey line and begin exporting product overseas.

When asked what he loves about distilling, Keegan replied, “It’s the people. What a great bunch. Distilling award-winning products is great, but sharing them with friends and family is that much sweeter.”

Advice for newcomers:

“Be cautious. It’s now a crowded marketplace and distributors do not play nice! And budget for four times the highest numbers you could dream of! When it comes to educating yourself, talk to the current bunch, run a budget, expect delays, give up the day job and save a bunch of dollars before you begin.”

Kirby Kallas-Lewis, OOLA Distillery

Seattle, Washington

ooladistillery.com

Before opening OOLA Distillery in 2010, founder and head distiller Kirby Kallas-Lewis was an international art dealer specializing in antique art from the South Pacific.

“I was tired of always being on the road and wanted to focus on a business that would allow me to work closer to home,” said Kallas-Lewis. With a deep love of food and wine and a drive for creating things from scratch, he pursued opportunities at restaurants and in the wine world, but nothing panned out.

Intrigued by the production of spirits, Kallas-Lewis spent nearly three years obsessing and researching American craft distilling, an awakening industry on the verge of being noticed. “I felt like with hard work and attention to quality products, design and marketing, one could make a real mark in the small distillery industry, and that was appealing.”

“Early on,” said Kallas-Lewis, “having enough money to take advantage of opportunities was an issue at every turn.” While it is a bit better now, “the exciting opportunities get more and more expensive as OOLA grows. So the issue of having enough capital never really goes away.”

The other primary challenge early on was finding a large enough space he could afford and permit. Fortunately, he was able to rent a space larger than he needed in the heart of Seattle’s vibrant Capitol Hill neighborhood and became a landlord building out the basics of a neighboring restaurant and bar on a site he could lease out. “The income from those spaces helps make our rent more reasonable.”

Using multiple low-capacity stills and other small “alternative” pieces of equipment in the beginning may have required more work on the part of Kallas-Lewis and his staff, but it allowed them to move forward with increased production and stay within the limitations of their financial resources.

“The whiskey workshops were especially important for me,” said Kallas-Lewis of his early education. “Just getting to work through the process from start to barrel was such a big help in putting it all into perspective. Learning from other students who were further along in the industry was also huge. I still keep in touch with people in the industry today that I met at ADI workshops.”

OOLA Distillery was one of the first distilleries to open in Seattle post-Prohibition, and today it ferments and distills over 200,000 pounds of grain, yielding small handcrafted batches of premium flavored vodkas, gins and whiskeys with a sense of place and a connection to the growers of the raw ingredients in them.

Looking forward, Kallas-Lewis is excited to grow and expand OOLA’s whiskey and gin categories as well as deepen his understanding of every aspect of spirit production, because, “there is no end to how much one can learn and grow in this business.”

Advice for new distillers:

“Don’t jump in and try to learn while running your own distillery. Equip yourself with knowledge first by taking any, and all, workshops and classes available on distilling. Then, find a job at a distillery and try working all aspects of the business from marketing and sales to choosing raw materials, fermenting, barrel aging and distilling. Make a business plan. Once you have a firm conservative plan, double your expenses and cut your projected income in half and know you might have to do it again. Only then raise a ton of money and plan on not getting a paycheck for ten years. If you feel like your passion can sustain that reality, it’s one of the coolest things to do out there. Convince yourself to do this and if you then believe it is truly what you want to do, go all in.”

Wes Henderson, Angel’s Envy and Louisville Distilling Company

Louisville, KY | angelsenvy.com

Unlike so many others’ stories of getting into craft distilling as a complete one-eighty from a lifetime spent in a career unrelated to spirits, Wes Henderson grew up and worked in the distilling industry. It wasn’t until later in life that he decided to launch his own brand motivated by an interest in creating something special with his father and son.

“Sometimes motivations don’t become clear until you have plenty of runway behind you to think about it,” said Henderson. “I liken the journey with Angel’s Envy to being strapped to a rocket ship with little time to reflect.”

A veteran distiller and consultant from years in the business, Henderson had enough of the technical knowledge of making bourbon down.

“I could write an entire book about starting a new business in one of the most competitive and highly regulated industries in the world,” he said.

So the act of making bourbon wasn’t as much of a challenge as brand development and understanding the regulatory landscape. “Those were the two biggest challenges, and we learned much of it on the fly. “

Looking back, Henderson cites the ADI workshops and a work ethic of “showing up every day to push the rock up the hill and never take ‘no’ for an answer” as keys to his success.

“The workshops were great opportunities for me to network, as we had much of the technical knowledge already covered. The relationships built with people experiencing similar challenges was invaluable. Some very successful brands were built by folks I sat next to in the workshops. I believe that a large number of the most influential and commercially successful craft brands got their start with ADI in one way or another.”

Today Henderson spends most of his time managing growth and is expanding his distillery in Louisville. Flanked by his sons Kyle Henderson (production manager) and Andrew Henderson (distillery operator), the family business continues to sample each barrel of their micro-batches of award-winning Kentucky straight bourbon finished in port wine casks while they work on a number of creative projects like their rum-finished rye whiskey.

Advice for new distillers:

“The actual distillation is only part of the puzzle. If you are the founder, it is an even smaller part, as you are building a brand and a highly regulated business. When I look at new operations, sometimes I see an imbalance of talent, which is not unusual for entrepreneurs. You can have the best distillate on the planet, but if you are unable to market it, it will be a short run. More importantly, while I would never encourage anyone to compromise their craft in the name of commercial success, it is possible to honor your craft integrity and create a profitable means of living. It doesn’t have to be one or the other.”

Tom Burkleaux, New Deal Distillery

Portland, OR | newdealdistillery.com

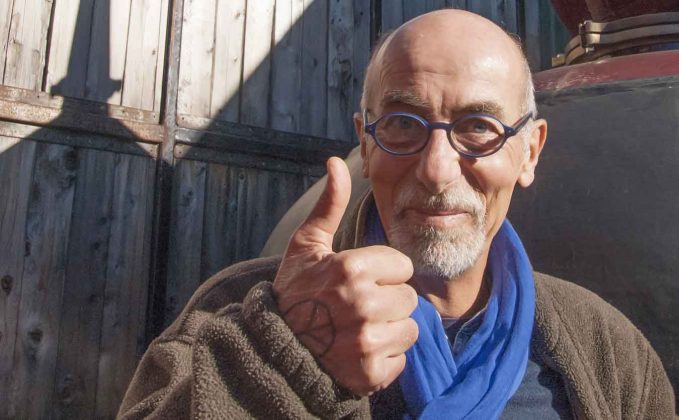

One day in 2001, at 35 years young, New Deal Distillery founder and distiller Tom Burkleaux joked with a friend about making his own booze. “My next thought was, why not?” It’s that sense of discovery and inspiration fostered by the city of Portland, a place pulsing with strong traditions in craft beer, wine and food, that jump-started his career in spirits.

“But there was never a business plan to ‘build a brand and sell it,’” said Burkleaux. “The goal was to have fun making something. And it still is.”

Thinking back to those early days, Burkleaux’s most significant obstacles were the absence of a roadmap to starting a distillery. There was no single resource where any information on any aspect of the business could be collected.

“The TTB [Alcohol and Tobacco Tax and Trade Bureau] wasn’t helpful back then. There were no websites, trade organizations, books, classes or any support I could find. At the end of the day, it was get a license, get a still and learn on your own.”

Burkleaux had the benefit of attending his first hands-on distilling workshop after being in business for a few years. His experience having wrestled with distilling as both an art and commercial enterprise allowed him to get the basics under his belt so that he could focus on the more nuanced and subtle lessons taught in a class. The workshops also helped him validate the work he was doing at New Deal Distillery and confirmed the team was on the right track.

“The courses are a forum to bring distillers together to learn from each other, and having been in the wilderness, I really appreciate that the industry didn’t just spring out of thin air. It had to be built from the ground up by its early members and supporters. ADI had, and continues to play, a strong role in this.”

The industry has come a long way in such a short time. Burkleaux now tells people he considers 2017 to be the first year craft distilling can call itself a “complete industry.” Help can be found at any stage now, from business plans, licensing, building, financing, procuring and operating distillation equipment, operational knowledge and marketing. Moreover, it’s those last pieces of the puzzle that have only recently fallen into place thanks to enough consumer awareness and demand for craft spirits.

“In the wilderness that was craft distilling from 2001 to 2007, you could only hope the industry would exist one day.”

Burkleaux loves everything about craft distilling and not being tied to a business plan gives him lots of room to play and experiment. He’s excited about new expressions of malt whiskey, exploring unique grains and new categories of spirits as well as new takes on traditional spirits like amaro and bitters.

New Deal Distillery is now making whiskeys, brandies, liqueurs, flavored vodkas, gins and pre-mixed cocktails like their Driftwood Manhattan — a collaboration with Mr. P. Andrew Taylor of Hammer & Tongs Vermouth.

“I love the community,” said Burkleaux. “In Portland, we adopted the ethos of the craft brewers helping each other. Learning from and being a part of the distilling community has been a great experience because there is always more to learn.”

Advice for new distillers:

“Don’t do it! — If your goals are strictly around making money. At least, I’m not the person to talk to in that case. But also understand that it’s a business, and all business is hard. Making good spirits is only one small piece of the puzzle. And know that most of your time will be consumed with the business of business: paperwork, marketing, cleaning, paying bills, bottling, etc. If you can handle the grind, then the enjoyment of bringing quality craft spirits to the world is worth it. I think hands-on workshops are great intros to the business on the distilling side. But once you get into the industry, being around other distillers is the best education. A lot of us are learning together every day. Don’t give up.”

Stephen Paul, Hamilton Distillers

Tucson, AZ | hamiltondistillers.com

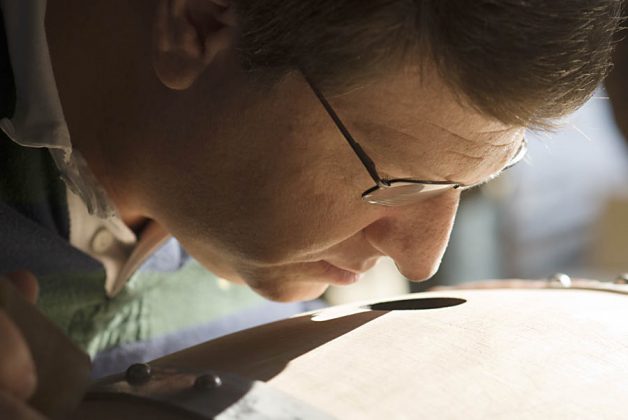

When Stephen Paul’s wife had the idea to dry malt over a mesquite fire instead of a peat fire for a hyper-regional Southwestern single-malt whiskey, the Arroyo Design furniture maker was intrigued. In 2007, at 56 and after 30 years of running a nationally recognized custom furniture company, Paul began his second career, this time using mesquite wood from the Sonoran Desert to distill his Whiskey Del Bac — four different American single-malt whiskeys.

“I really didn’t have any plans at that point other than to just see if I could make a whiskey that would taste good,” said Paul. “The whiskey just kept getting better until I had an old customer from our mesquite furniture business offer to fund an official product development phase in 2012, from which I took the product to the local Tucson marketplace with great success. It was then I got serious about making a business of it.”

The most significant challenges Paul faced early on were learning how to distill, malt barley and design a 5,000-pound batch prototype tank-based malt house. Raising capital to fund everything was no walk in the park either.

To overcome the distilling and malting knowledge gap, Paul did a ton of reading and ultimately attended a week-long ADI workshop in Petaluma, CA, after acquiring a 40-gallon still.

“I made a whole bunch of mistakes, which taught me a lot, too.”

Paul praised distiller Jordan Via of Savage & Cooke and Breckenridge Distillery for running the workshop. “He was great,” said Paul, “And I also met Nancy Fraley there, who later helped me become a better distiller by critiquing my distillate and being very blunt about the cuts I made.”

Paul remembers the great speakers and presentations on marketing, using Anton Paar products, distillery layouts, label design, branding and safety. “There was a presenter from Cask Liquors in San Francisco who discussed ways to approach an account that has stayed with me ever since. ADI conferences are great for the seminars and networking with industry peers.”

Paul is thrilled to be fostering his next generation of distillers and recently passed the title of head distiller to Nathan Thompson Avelino, who with Hamilton’s assistant distiller, Ramon Olivas, is making fantastic award-winning whiskeys. Hamilton is expanding their barrel program to include a variety of special-finish casks, including ex-Madeira, ex-Cognac, Calvados casks and a big Pedro Ximenez cask that’s been in continuous use for 100 years.

But that’s not the only expansion Hamilton Distillers is taking on. Now in an 8,000 sq. ft. facility, the distillery is expanding the tasting room into some unused office space, which will free up more space for barrel storage. The installation of a new chiller with a water cooling tower component will reduce their utility bills and improve water use efficiency too.

Advice for new distillers:

“If you think you can make a product that stands out in the very crowded field of craft spirits in the U.S., then assume you need to raise at least $2.5 million to get going and have operating capital to get into the black. Talk to other craft distillers to get their advice about the economics of it all, as well as other aspects. Don’t undersize your system and don’t assume sales in your town or general region will make you profitable. I personally don’t think you can make any money off anything less than a 500-gallon still system. Expect to spend a ton of money on marketing. I was very naive about that, just thinking if I made a great whiskey people would knock down my door to get it. There are so many good craft spirits out there, and you have to really get the word out about yours. Also, don’t think you can distill your product, manage your distillery, market your product, do all the admin, etc., all on your own—you’ll need a lot of help. We’re a staff of seven, and I could use three more full-time people right now if I could afford the payroll.”

David Woods,

Wiggly Bridge Distillery

York, ME

wigglybridgedistillery.com

When we asked David Woods Sr. what motivated him to get into the distilling business, he said, “I found it very intriguing, and I was at a stage in my life where it was something to do. Along with starting an additional family business, this time with my son at my side from the time of its inception.”

In 2011, at 56, David Woods Sr. and his 26-year-old son, “Little David,” embarked on a family owned and operated business with the goal of making their own premium whiskey. This was after making a few small batches of “bush rum” from molasses, sugarcane and “fruits from the rainforest” during a few winter vacations to a family home on the Caribbean island of Montserrat.

The Woods’ biggest hurdles were not the distillation process so much as working within the state and local permitting process.

“With that said, I never look at things that we do as challenges,” said Woods Sr. “I view them more as an opportunity for change either within ourselves or others that you’re dealing with. I found over my lifetime you can always get to a win-win.”

To level-set their self-taught knowledge of distilling with what was industry standard at the time, the father-son duo attended an ADI workshop at Breckenridge Distillery in Colorado. That codified the knowledge they possessed at the time and gave them the self-assurance to proceed with opening up Wiggly Bridge Distillery with a higher likelihood of success.

What Woods loves most about distilling is the opportunity to create products from raw materials that are appreciated by the people who enjoy the whiskey, bourbon, barrel-aged rum, white rum, vodka and gin he and his son are making. The goal is to create high-quality craft spirits and expand the business to maximize their self-imposed production cap and one day see Wiggly Bridge become a legacy business they can pass on to grandchildren.

Advice for new distillers:

“Learn as much as you can about fermentation. Learn as much as you can about marketing and distribution. Learn as much as you can about financing and cash flow. And finally make sure you are very, very well-funded. Understand that there is a high likelihood that you will remain unprofitable for the first five years (i.e., two years of cash to burn through in the beginning and then understanding and calculating cash flow to offset that cash burn through sales after year two.) Oh, by the way, running the still is probably the easiest thing to learn and do.”

The Next Generation

It’s clear from just this sampling of first-generation American craft distillers how integral it is to develop a community of resources that can help teach and support its members.

“It’s a melting pot of institutional knowledge within the craft industry,” said David Woods. “I love to attend the events to help others and be helped by others on this path. A rising tide floats all boats, and we all need to pay it forward.”

That’s sage advice for the next generation of American craft distillers and spirit enthusiasts planning to join the ranks of an industry experiencing exponential growth. It’s also an essential reminder of how far some of our industry leaders have come thanks to the help they received from the village of peers, mentors and educators affiliated with ADI.