Yes, Shanna Farrell, we forgive you.

Even though Distiller and ADI are headquartered ten miles from you in Berkeley, we forgive you for not including us in your new best-selling hardcover A Good Drink, In Pursuit of Sustainable Spirits (Island Press, 2021). Sure, your book is a highly readable guide to how bars and distillers of all sizes are seeking the illusive ROI on sustainable spirits. And sure, in whiskey, agave, gin, vodka, rum, and brandy, you plot the course of over a dozen craft distillers and barkeepers trying to find green money in green practices.

Yet while you take us on a fun journey, you offer limited answers to the big question for craft distillers seeking sustainability — “where’s the money?” So we at Distiller feel like it’s our obligation to you, dear distiller, to help Ms. Farrell answer the question. We’ll use her entertaining book for points of reference, and go a bit farther down sustainability lane to find the money.

Corn, COVID and Climate Change

Farrell, who hails from the University of California at Berkeley Oral History Project, blames her drive to write the book on the isolation caused by “drinking in the time of COVID.” As is fitting for an American (where whiskey rules the roost), she starts her sustainability search with heritage corn. You’ll recall that the Winter 2021 issue of Distiller covered “The Pied Piper of Heritage Corn” Gary Hinegardner of Wood Hat Spirits. Gary, a well-traveled agronomist, barrel technician, and polymath on all things corn, bangs the drum for all native corns. At the same time, he curses the widely-used Yellow Dent, which he reminds us is genetically modified (GMO), a proprietary breed of industrial agro giant Monsanto, is the #1 food eaten by pigs, and is classified by the USDA as an “insecticide.” It’s an “insecticide,” that is, because pests, when they eat Yellow Dent, die quickly from GMO sugar crystal-induced intestinal blockage.

Unwittingly and without mentioning Hinegardner, Farrell follows that same corn trail as she recounts meeting High Wire Distilling’s Ann Blackwell, a fan of Jimmy Red corn, a heritage strain rescued from near extinction by a crew of botanists from Clemson University. Jimmy Red, like other native corns, is not a GMO, not an “insecticide,” and delivers a smoother bourbon than yellow dent — no burn on the front of the tongue, no burn on the back. Once Blackwell released it back in 2016, High Wire’s Jimmy Red bourbon sold out in a record 11 minutes. And that reveals the first and most important way to put more green in your pocket from greener spirits: Make a smoother bourbon and sell a lot of it. That’s why Wood Hat’s Hinegardner predicts that in the future, all bourbons will have their own flavor of heritage corn and leave Yellow Dent to the pigs.

But a funny thing happens as she weaves her corn tale. Farrell reminds us of the environmental story of the century: COVID-19. If not for COVID, 50% of bars would not have failed. If not for the pandemic, 96% of distillers would not have discovered RTD, D2C, and other pivots made necessary by the pandemic, including PPE, staff distancing, how to distill and bottle hand sanitizer, and how to master the virtual tasting room. And if not for the shutdown, stay-at-home drinkers would not have avoided viral spread and environmental hazards by drinking at home, going online for Zoom happy hours and have the online time to learn about craft variations like local cannabis-infused gin, ethnic vodka, heritage corn-based bourbons, shochu, mezcal, and ready-to-drink everything cocktails.

And Then There’s Agave and Brandy

In 1949, Mexico did what the French wine and American bourbon industry had done earlier — regulate an appellation to artificially limit supply and boost demand and prices. It was that year that Blue Weber agaves from Jalisco were named the only authorized source of tequila. In 1994, Mexico updated the regulation to include nine south-of-the-border states as Denomination of Origin (DO) for tequilas.

At the time, Mezcal, made with non-Blue Weber agaves, was unregulated. That lasted until 2005, when the Mezcal Regulatory Council (CRM) set up an industrial monopoly of its own. And as it nearly always does, that age-old monopoly trick worked. By 2018, 5,000,000 liters of Mezcal was produced, a 38% rise from five years prior. As an example, Farrell tells the story of Mezonte Distillery’s Pedro Jimenez Gurria, whose “mixto tequila” doesn’t have to include Blue Weber agaves, while taking advantage of the outsized growth in the growth of all agave-based beverages. Did Pedro do something particularly green? Not really. Neither tequilas nor mezcals are particularly environmentally-friendly. What’s sustainable about mezcal? Not much. Except it’s tasty, different, broadly available, trendy, and now, selling briskly.

After mezcal, craft brandy makes a cameo in Farrell’s sustainable drinking tour, alongside the bar/restaurant trash problem and California’s wildfires, Thad Vogler and Eric Johnson’s Bar Agricole in San Francisco, known for its brandies and its “bartenders sell through stories” philosophy, was a pioneer in fighting bar waste and sourcing spirits locally. Farrell notes that the average bar/restaurant generates 100,000 pounds of trash each year — an annual nationwide food waste total of 33,000,000,000 pounds (that’s billions with a “B”). The US wastes 40% of our food. And 15.7% of our energy and 80% of our fresh water is spent on food production.

To do its part, bars such as London’s Tin Roof bar chills its drinks in advance and uses no ice, which saves energy, and delivers undiluted drinks that get out faster. For Oakland, California-based St. George Spirits, which produces eau de vie brandy each Fall, California’s recent spate of environmentally-caused forest fires has devastated fruit growing. So distiller Lance Winters and partner Dave Smith now have to source pears from Colorado to avoid brandy that tastes like smoke.

Why Rum Rocks Sustainability More than Gin and Vodka

In a book on sustainable drinking, it would have been a Cardinal Sin if Farrell failed to honor the American craft distilling industry’s all-time sustainability giant, Karen Hoskin of Crested Butte, Colorado-based Montanya Distillers. Montanya, famous for its rums, is one of only 3 distillers that is a certified B Corp. Her plant is 100% wind-powered, carbon offset, and its buildings are warmed by recycled heat from their stills. Hoskin’s path to zero-waste includes managing bio waste, being plastic neutral, having certified cradle-to-cradle bottles and packaging, Her American-grown sugar cane comes from Lula, a Louisiana-based co-op that generates all its electricity and boiler-firing heat from the sugar cane itself.

Hoskin, who holds a public health master’s degree in epidemiology, is highly aware of her environmental metrics. For example, while her sugar cane is the distilling industry’s gold standard for energy efficiency, cane itself is a water-intensive crop — growing the cane for each teaspoon of rum takes 9 gallons of water. Rum sugar from Mauritius is water-intensive Demerara cane, and Barbados sugar is from less water-intensive and less expensive beets.

In addition to energy, packaging and water intensity, another big sustainability theme in rum is additives. As a personal drinking habit, Farrell avoids Campari for her beloved Negroni (ingredients: gin, sweet vermouth, orange twist). Why? Because Campari’s red color came from cochineal beetle juice until 2006, when the company switched to red dye number 40. And while the dye is classified by the FDA as “GRAS” or “Generally Recognized as Safe,” number 40 has been linked with cancer.

Speaking of ingredients, it turns out that rums from Guatemala and Panama have long included sweeteners and colors, in contrast with less-doctored rums from Jamaica, Barbados or St. Lucia. Master rum maker Richard Seale of $100-a-bottle Foursquare (which Farrell calls “the Pappy Van Winkle of rum”), is also founder of the Guardians of Rum, who document and celebrate the cultural identity and authentic practices of rum makers. Seale and his Guardians are 100% against additives.

Vodka and gin (which starts with vodka, and can include any herb as long as juniper is one of them), by contrast, have taken less leadership in sustainability. This is largely due to the fact that most American vodka and gin products start life as neutral grain spirits (NGS) bought from Midwest Grain Products (MGP) of Indiana, which is famously tight-lipped about its processes, ingredients or environmental metrics.

In addition to this issue’s cover girl Vanessa Gravesande-Braxton, another non-NGS-based vodka brand is owned by Scott and Todd Leopold of Leopold Brothers Distillers in Denver. Scott is an environmental engineer. Todd is a brewer. And they own a 30,000 square foot malt house for their barley. The brothers grew up in an environmentally-conscious family, as their father Bob followed famous conservationist and author of A Sand County Almanac, Aldo Leopold. The Leopold brothers source all their barley locally to limit transportation. They use 100% solar power, and they are famously water-conservative. Malting barley involves tricking the grain into thinking it’s still in the ground so it sprouts and becomes malt. Their mash tuns are wood rather than steel to conserve water and energy and add a house flavor. Their vodka, called Silver Tree, therefore, is based on sustainable practices. Their gin is produced by fractional distilling, where each botanical is distilled individually, because each botanical is cooked at a different temperature and added at a different time.

What Farrell Forgets about Sustainability: Packaging Matters

Energy and water and carbon footprint reduction, local sourcing to limit transportation, efficient local craft processes such as barley malting, waste reduction, and ingredient safety and transparency are major components of distillers’ ability to manage their environmental footprint and costs.

But here’s Farrell’s big sustainability miss: Between 28% and 49% of a spirit’s cost and 51% of a spirit’s carbon footprint comes from making, labeling and transporting its glass bottles. America’s 16,000 spirits-based products marketed last year used 60% of the 12,700,000 tons of America’s glass bottles, 60% to 70% of which came from China, and only 31.3% of which we recycle. A 25% reduction in distillers’ glass bottle usage would save more money in materials use, energy, water, carbon footprint, disposal and transportation costs than all other available savings combined.

There are technology innovators working on the spirits packaging conundrum right now. The most promising solutions are in the niche known as circular packaging. According to a Deloitte study, Singapore-based EcoSpirits, working with Pernod Ricard, is a leader in circular. Instead of bottling your booze at the still and shipping them to bars or distributors, the producer sends bulk liquid to local markets, where the customer’s order is decanted into a reusable ecoTote. Once at the bar, the customer fills bottles in the bar, or dispenses the liquid right into glasses via an integral tap. The empty containers are returned to the processing plant for refilling. Over its lifetime, the ecoTote eliminates over 1,000 single-use bottles. Each glass of spirits from an ecoTote saves 30 grams of carbon emissions, in addition to the 120 grams per serving that is saved through the company’s Forest Program tree planting initiative.

Other solutions other than circular are also in the works. In beer, Colorado-based BrewVo has figured out how to extract water and alcohol from kegs before shipment, and add it back at the destination. Another producer with a catchy name is London-based Packamama, which makes lie-flat bottles that Bloomberg reports are “87% lighter than traditional cylindrical glass ones and 40% smaller so that twice the amount of product can be shipped in the same space.”

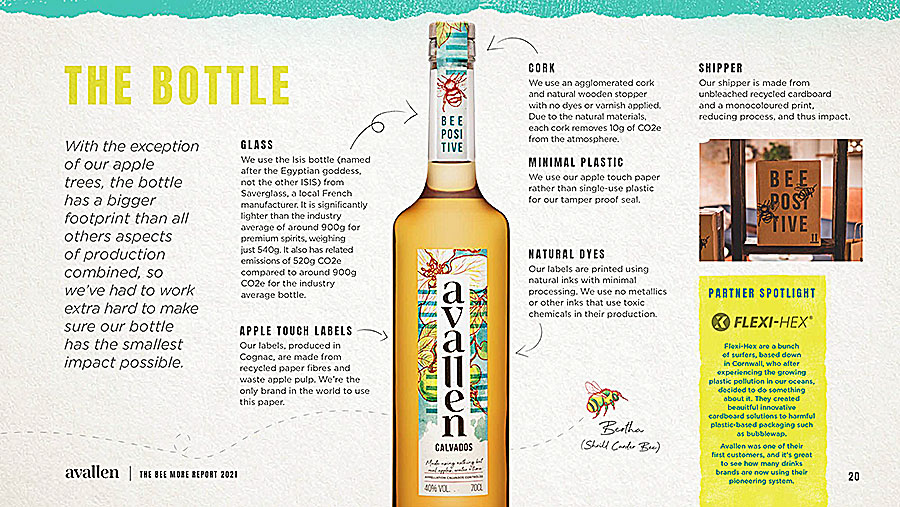

In France, craft Calvados producer Avallen now uses recycled glass bottles and waste-apple-pulp labels. Avallen has been certified carbon negative, cutting 2.73 kg per bottle. Co-founder Tim Etherington-Judge reports that each bottle is made with 1.2 liters of water, which is 70% to 95% less than any other spirit category — that compares to 13 liters of water for a bottle of bourbon, for example. The company’s bottle weighs less as well — 540 grams versus 900 grams for most premium spirit bottles. And their natural wood stopper is made without dyes or varnish. The Calvados brand is also using a Frugalpac paper bottle and a 4.5 liter container by Ecospirits.

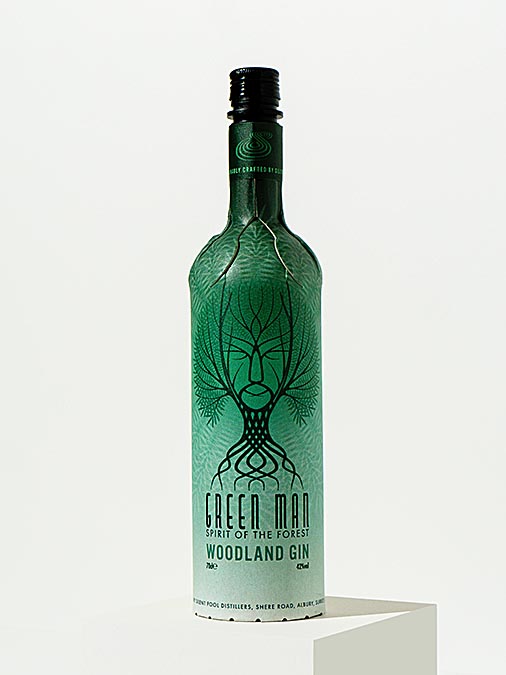

Speaking of paper, last year’s Earth Day featured a world’s first: English gin maker Green Man Woodland Gin was offered in a paper bottle made by Frugalpac, five times lighter than glass alternatives. Its paper outer layer is 94% recycled, and the inner pouch plastic liner is also recyclable.

The Sustainable Cost Conclusion for American Craft Distillers

As a prologue to the craft distiller’s search for sustainability solutions, cost savings and sales growth, Shanna Farrell’s A Good Drink checks the box. She introduces some thought leaders and superstars. Karen Hoskin in energy and waste reduction and sourcing, Ann Blackwell in heritage corn, Richard Seale in purity of ingredients, London bars in waste reduction, Leopold Brothers in sustainable local processes.

She hit many of the main topics. Energy savings, waste reduction, local sourcing to save transport costs and lower carbon footprints, and sustainable processes. And she reminded us that sustainability doesn’t compute if we can’t sell our stuff. In fact, if the choice is between going completely green or selling more stuff, 99.5% of the time, we’ll choose to sell more stuff.

But where she misses the mark is in plotting the course forward. And clearly, the course forward involves more innovation on the packaging front. As the saying goes about youth sports and cleaning sweaty socks, nobody gets into craft distilling because they dream of the glory of shipping heavy glass bottles cross-country. Finding innovative and resource-reducing solutions for packaging and delivering craft spirits to thirsty customers with less environmental damage unlocks huge value for the craft producer. Wood Hat’s Gary Hinegardner says about heritage corn, “in the future, every whiskey will have its own corn,” And you read it here first in Distiller: In the future, the most competitive craft spirits will be those with the most eco-friendly way to get their product to drinkers’ lips. •