Authors: Brad J. Berron (James B. Beam Institute for Kentucky Spirits, The University of Kentucky), Jon Brown (Castle & Key Distillery), Jason Gambrell (Castle & Key Distillery), Travis Cantrell (Bardstown Bourbon Company), Meghan Mattingly (Bardstown Bourbon Company), Sarah A. Wilson (James B. Beam Institute for Kentucky Spirits, The University of Kentucky), Jarrad Gollihue (James B. Beam Institute for Kentucky Spirits, The University of Kentucky), Harmonie M. Bettenhausen (Center for Craft Food & Beverage, Hartwick College)

Distillers looking to tap into international markets face a diverse regulatory landscape that can present a significant challenge. In particular, U.S. distillers often overlook limits on ethyl carbamate (EC) in distilled spirits imported to European and Canadian markets. Ethyl carbamate is classified as a suspected carcinogen in the E.U. and Canada (Pang, Li, et al. 2017). Regulatory limits may be challenging to meet for distillers inexperienced in EC management. Previous EC research places little emphasis on American whiskeys, and there is a lack of literature on EC levels in bourbons produced at craft scale or on continuous stills.

The University of Kentucky’s Beam Institute partnered with Castle & Key Distillery to determine how distillery operations impact the levels of EC in bourbon products. This work was funded by the American Distilling Institute’s Distilling Research Grant program. The team also partnered with experts from Bardstown Bourbon Company for EC analysis and Hartwick College for grains analysis. We discovered that you can manage EC levels with the existing tools of distilling, namely grain selection, dilution, and copper stills and plates.

EC Origins

The EC that ends up in the bottle starts from glycosidic nitrile (GN) compounds in the grains (Riffkin, Wilson, et al. 1989). These GN compounds undergo several reactions in the fermenter and still to ultimately form hydrogen cyanide. From there, copper present within the still or doubler catalyzes the reaction of hydrogen cyanide into EC. This conversion of hydrogen cyanide to EC occurs in the still but will also continue in the barrel, resulting in EC levels that increase through the aging process.

Our own data shows that the EC levels in the cistern were only about half of the EC levels found in matured barrels of the same liquid, a finding that has been reported in Scotch (Aylott, Cochrane, et al. 1990) and sugarcane spirit (Alcarde, Souza et al. 2014). This finding supports the theory that EC levels in fresh distillate are not the same as EC levels in the eventual product. To account for the further conversion of hydrogen cyanide to EC after distillation, several labs offer test methods that drive the reaction to completion before analysis. While these pre-maturation analyses are strong predictors of EC levels in the matured product, the final spirit must be tested for compliance.

Selecting Grains for EC Management

Since EC comes from the grain, grain bills have a major impact on the final EC. The GN compounds that result in EC formation are found largely in malted barley, and our preliminary studies showed a clear increase in EC as malt levels in the mash bill increased. As a rough estimate, doubling the malt in the grain bill resulted in double the EC levels. Therefore, dialing back the malt content is one potential way of managing EC levels in the spirit.

Another approach is to use malts that have no or low levels of GN. Many GN-deficient breeds are available in European markets, but there are currently only a handful of spring-planted barleys in the U.S., and of those, only one (Odyssey by Limagrain Cereal Seeds) is widely available through large-scale malting channels. There has been recent movement in public barley breeding programs to develop lower and no-GN varieties that are regionally adapted and more widely available. Since GN is highly influenced by the malting process (time, temperature, and moisture level all exacerbate GN levels), it can be difficult to pinpoint exactly where a GN measurement will lie for each batch malted. There are several low-GN (< 1 mg/kg GN) barley varieties, but the proportion of GN that will convert to EC is currently unknown (Morrissy, Thomas, et al. 2023).

Using Copper as a Weapon Against EC

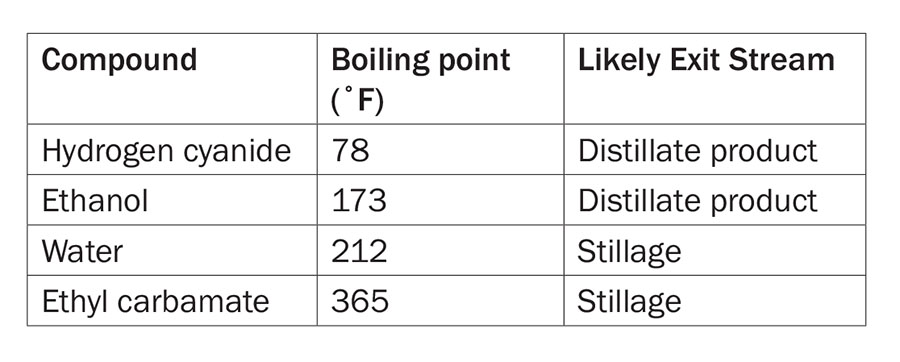

The most important concept for EC levels in a grain whiskey product is the volatility of the compounds. EC is much less volatile than water, and hydrogen cyanide is much more volatile than ethanol. Therefore, any EC that is formed prior to or inside the still will stay in the water phase of alcohol distillations. This means that EC formed in fermentation or the still will generally exit with the stillage and never reach the barrel. On the other hand, unreacted hydrogen cyanide will leave the still with the spirit, leading to eventual formation of EC in the final product. As a result, distillation is the foundation of EC management with many spirits. By bringing your spirit into contact with copper early in distillation, EC is formed within the still (rather than the barrel) and drops out with the stillage during distillation. In other words, you can use copper’s catalyzing properties to your advantage in reducing EC.

To ensure that EC is removed from the spirit inside the still, it is important to make sure that EC forms early in the production process. EC formation is accelerated by copper and heat, so providing significant copper contact during distillation can help drive formation. Results from our data showed that copper contact above the feed is most important for EC management. This can be seen at Castle & Key Distillery, which offers its clients the option of a beer feed at different locations in the column still. For feeds one stage closer to the top of the column, there was a significantly higher EC level in the spirit product. This is likely because a lower feed sends the volatile compounds past more copper as they try to exit the column in the distillate stream. If hydrogen cyanide makes it completely through the distillation system, it will eventually increase EC levels in the barrel. While counterintuitive, accelerating the formation of EC in your still eliminates the ability for EC or EC-forming hydrogen cyanide to reach the barrel.

Caustic Cleaning

If changing the feed is not an option for providing more copper contact, we found that caustic cleaning is a reliable approach for lowering EC. When using a higher feed stage, the spirit from the batch immediately after caustic cleaning was significantly lower in EC than spirit from later in the cleaning schedule. Since copper helps to speed up the formation of EC, cleaning ensures that copper can interact with the liquids and vapors in the column.

Higher-Proof Low Wines

We tested several other concepts in EC management. Increasing the proof of the low wines coming off the column still did not have a significant effect on product EC. This makes some sense considering the large differences in volatility between hydrogen cyanide and EC. Most EC present will exit with the stillage, while most hydrogen cyanide will exit with the distillate. These compounds were not influenced by subtle changes in “cut” or distillate alcohol content.

Bottling Proof

The bottling proof is another consideration for EC management. If your desired sensory profile shines at a low proof, you’re in luck: The concentrations of both EC and alcohol are lowered by simple dilution. By diluting from 130 to 80 proof, there is a predictable lowering of EC by 41%.

Takeaways

These studies were exclusively carried out using a bourbon mash bill on a 20-stage, pure copper, 32” Vendome column still using continuous production techniques common to the bourbon industry. We should also note that the doubler is another downstream location for distillation and copper contact. The doubler liquids were held at 45% of the doubler volume and intermittently pumped back into the beer well, allowing accumulated EC to re-enter the column and exit with the stillage.

Lessons learned here can be carried over into other spirits. There has been extensive prior work on EC control in Scotch production, where similar grain selection and copper contact strategies are effective at lowering EC. Given these similarities between whiskey classes, North American distillers should be aware of potentially high EC levels when making pure-malt whiskeys in the absence of strict production methods and/or low-GN malts.

In summary, you must think about the EC levels in your product if you wish to tap into the growing international popularity of American spirits. The type and amount of malt used in your spirit will have a major impact on the potential for EC in your spirit. Since specialty malts aren’t readily available, you will need to manage EC at the level of your distillery operations. The most powerful approach to controlling EC with distillery operations is ensuring significant contact with clean copper. In the end, you can achieve low-EC spirits ready for the European market using the same copper-rich techniques that drive flavorful spirits.

References

Alcarde, A. R., L. M. Souza and A. M. Bortoletto (2014). “Formation of volatile and maturation‐related congeners during the aging of sugarcane spirit in oak barrels.” Journal of the Institute of Brewing 120(4): 529–536.

Aylott, R., G. Cochrane, M. J. Leonard, L. MacDonald, W. MacKenzie, A. McNeish and D. Walker (1990). “Ethyl carbamate formation in grain based spirits: Part I: post‐distillation ethyl carbamate formation in maturing grain whisky.” Journal of the Institute of Brewing 96(4): 213–221.

Morrissy, C. P., W. Thomas, H. M. Bettenhausen, S. P. Fisk and P. M. Hayes (2023). “Glycosidic Nitrile and Ethyl Carbamate in Malting Barley.” Artisan Spirit 12(1): 78–82.

Pang, X.-N., Z.-J. Li, J.-Y. Chen, L.-J. Gao and B.-Z. Han (2017). “A comprehensive review of spirit drink safety standards and regulations from an international perspective.” Journal of Food Protection 80(3): 431–442.

Riffkin, H. L., R. Wilson, D. Howie and S. B. Muller (1989). “Ethyl carbamate formation in the production of pot still whisky.” Journal of the Institute of Brewing 95(2): 115–119.